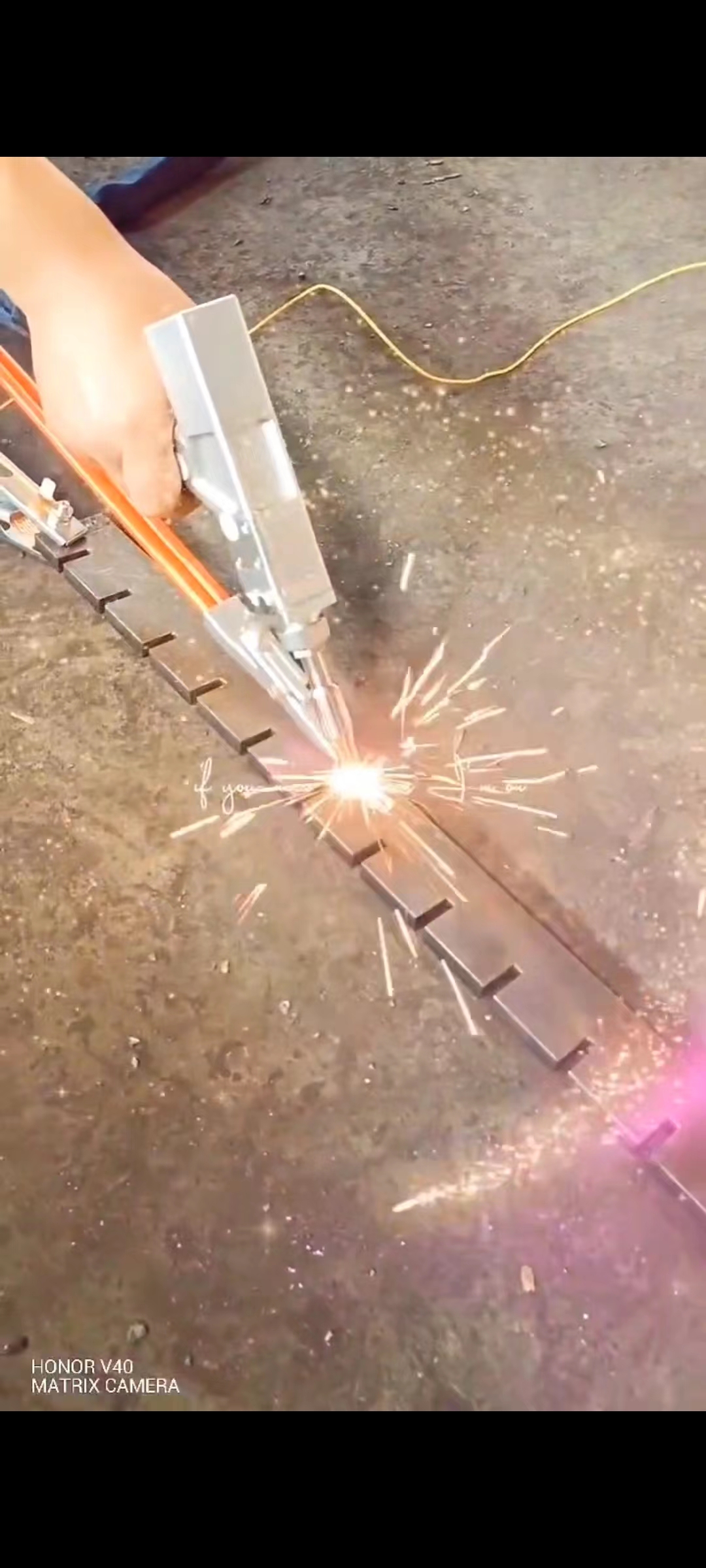

Umgaqo wokusebenza:

Itotshi ye-welding isebenzisa ubushushu obuveliswa ngumbane ophezulu wangoku kunye nophezulu kwamandla ombane ukuqokelela ekupheleni kwetotshi ye-welding, kwaye ucingo olunyibilikisiweyo lungena kwindawo ukuze ludityaniswe.Emva kokupholisa, into edibeneyo idibaniswe ngokuqinileyo kwenye.

Amandla etotshi axhomekeke kumandla we-welder kunye ne-welding material.

Welding totshi welding isiphumo abaqeqeshiweyo, ukhuseleko welding, isantya fast.

Itotshi ye-welding inokusebenza okuthembekileyo, ukugcinwa okulula kunye nokulungelelaniswa okufanelekileyo.

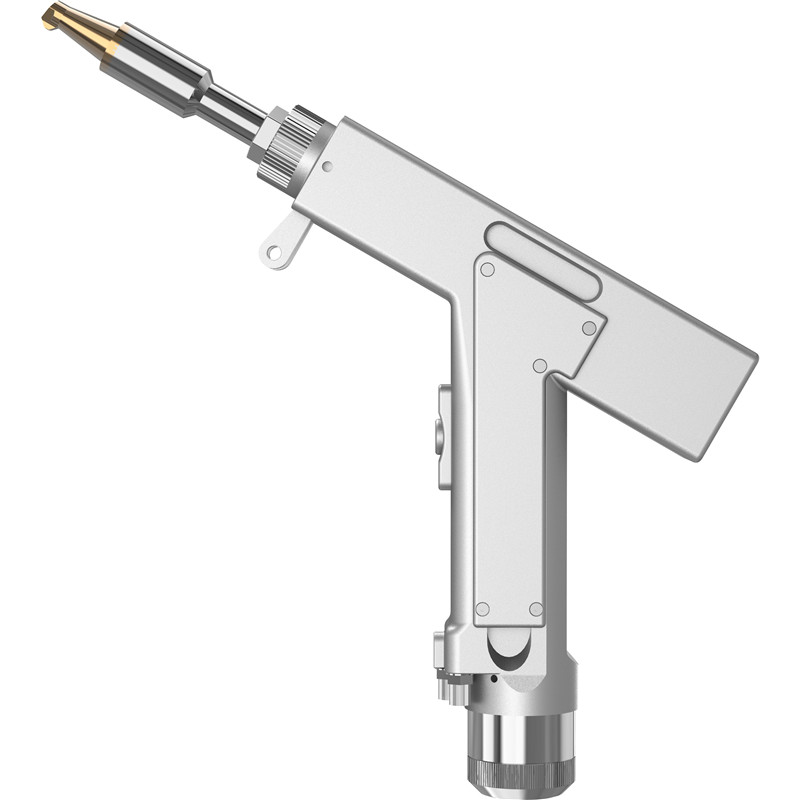

Umpu we-welding awusebenzisi umbane, gcina intsimbi, utyalo-mali lwezixhobo luncinci kunye nezinye iingenelo.

Ukusetyenziswa kwetotshi ye-welding:

Xa sifuna ukuwelda, kufuneka siqale sikhethe imodeli efanelekileyo kunye ne-caliber ye-welding ye-nozzle eyahlukeneyo ngokobukhulu, ubukhulu kunye nokuhanjiswa kwe-thermal yee-welds ezahlukeneyo.Ukusebenza, vula iqhosha le-acetylene kuqala, kwaye emva koko ukhulule i-oksijini kancinane, ulayite ibhloko ye-acetylene, emva koko ubushushu belangatye aliphezulu, i-nozzle iveza iileyi ezimbini ze-core flame core, ukongeza, ngenxa ye-acetylene yokutsha ngokugqithisileyo ayiphelelanga, rhoqo umsi omnyama, ukukhanya kancinane ngaphambi kokuba enye impembelelo ye-oksijini kukunciphisa umsi omnyama.Kwi-welding, lungisa i-oxygen switch, ukwenzela ukuba i-oksijini kunye ne-acetylene igesi efanelekileyo, ukutshisa okwaneleyo, ukushisa okuphezulu.Xa i-welding idibanisa, i-joint ye-weldment itshiswa kuqala kwiqondo lokushisa elibomvu, kwaye intonga ye-welding itshiswa kwi-weld kwaye izaliswe kwi-joint.Emva kokunyibilika kunye, ilangatye le-oxyacetylene lingarhoxiswa, kwaye i-welding igqitywe ngokupholisa.

Ukukhethwa kwe-electrode:

Ingaba i-welding okanye ukulungiswa, kuyimfuneko ukukhetha i-electrode efanelekileyo njengentsimbi yokuzalisa.Amandla kunye nokusebenza kokubambisana akuhambelani kuphela nenkqubo ye-welding, kodwa ihambelana ngokuthe ngqo kwizinto eziphathekayo ze-electrode esiyisebenzisayo.

Ngokuqhelekileyo, indawo yokunyibilika yentonga ye-welding ayifanele ibe phezulu kune-melting point of the welding parts, kungenjalo akulunganga ukuqonda i-weld metal pool kwinkqubo ye-welding, ukwenzela ukuba ukubunjwa kwe-welding kubi.

Ixesha lokuposa: Nov-29-2022