Laser Ukucoca umenzi wentloko

Umenzi wentloko yokuCoca iLaser,

eyona ntloko yokucoca laser, China laser yokucoca intloko, umpu wokucoca laser ophathwa ngesandla, i-laser yokucoca umpu, i-laser yokucoca umzi-mveliso wentloko,

Ikhuselekile.– Ekhuselekile

Uphando oluzimeleyo kunye nophuhliso lwenkqubo yokukhangela ukhuseleko, ukuseta inani lee-alamu zokhuseleko, ukhuseleko kunye nokuzinza

Ukugcina ixesha - ngokufanelekileyo kwaye kulula

Isibuko sokujolisa, idrowa yesipili sokukhusela, indawo efanelekileyo

Ukukhanya - Ukukhanya kunciphisa umthwalo

Ubungakanani obuncinci, ubunzima obulula, ukusebenza okuguquguqukayo, kulula ukuyisebenzisa

Umgangatho - i-welding entle- ukusebenza okuzinzileyo

Amandla aphezulu e-welding, i-deformation encinci, ubunzulu bokunyibilika okuphezulu

Ukusebenza - Iimpawu ezininzi

Inkxaso ebambe ngesandla i-welding eqhubekayo, ukuwelda, ukucoca, ukusika, "isandla" "ukususela" - umzimba, ukugunyazwa kwephasiwedi

Intloko ye-welding ephezulu i-handheld welding cut head eqaliswe ngo-2019. Imveliso igubungela izibhamu ze-welding ezibanjwe ngesandla kunye neenkqubo zokulawula eziziphuhlisileyo, kwaye zixhotyiswe ngama-alamu amaninzi okhuseleko kunye namandla asebenzayo akhuselekileyo kunye nezicwangciso zokukhanya.Le mveliso inokutshintshwa kwiintlobo ezahlukeneyo ze-fiber lasers;i-optical optical kunye noyilo olupholileyo lwamanzi luvumela intloko ye-laser ukuba isebenze ngokuzinzileyo ixesha elide phantsi kwe-2000W.

1) Qinisekisa ukusekwa okuthembekileyo phambi kokunikezelwa kombane.

2) Intloko yokuphuma kwe-laser idibene nentloko ye-welding.Nceda ujonge intloko yemveliso ye-laser ngononophelo xa usebenzisa ukuthintela uthuli okanye olunye ungcoliseko.Xa ucoca intloko ye-laser output, nceda usebenzise iphepha elikhethekileyo lens.

3) Ukuba isixhobo asisetyenziswanga ngokuhambelana neendlela ezichazwe kule ncwadana, sinokuthi sisebenze ngokungaqhelekanga kwaye sibangele umonakalo.

I-4) Xa utshintsha i-lens yokukhusela, nceda uqinisekise ukuba uyayikhusela.

5) Nceda uqaphele: Xa usebenzisa okokuqala, Musa ukukhupha ukukhanya xa ukukhanya okubomvu kungabonakali.

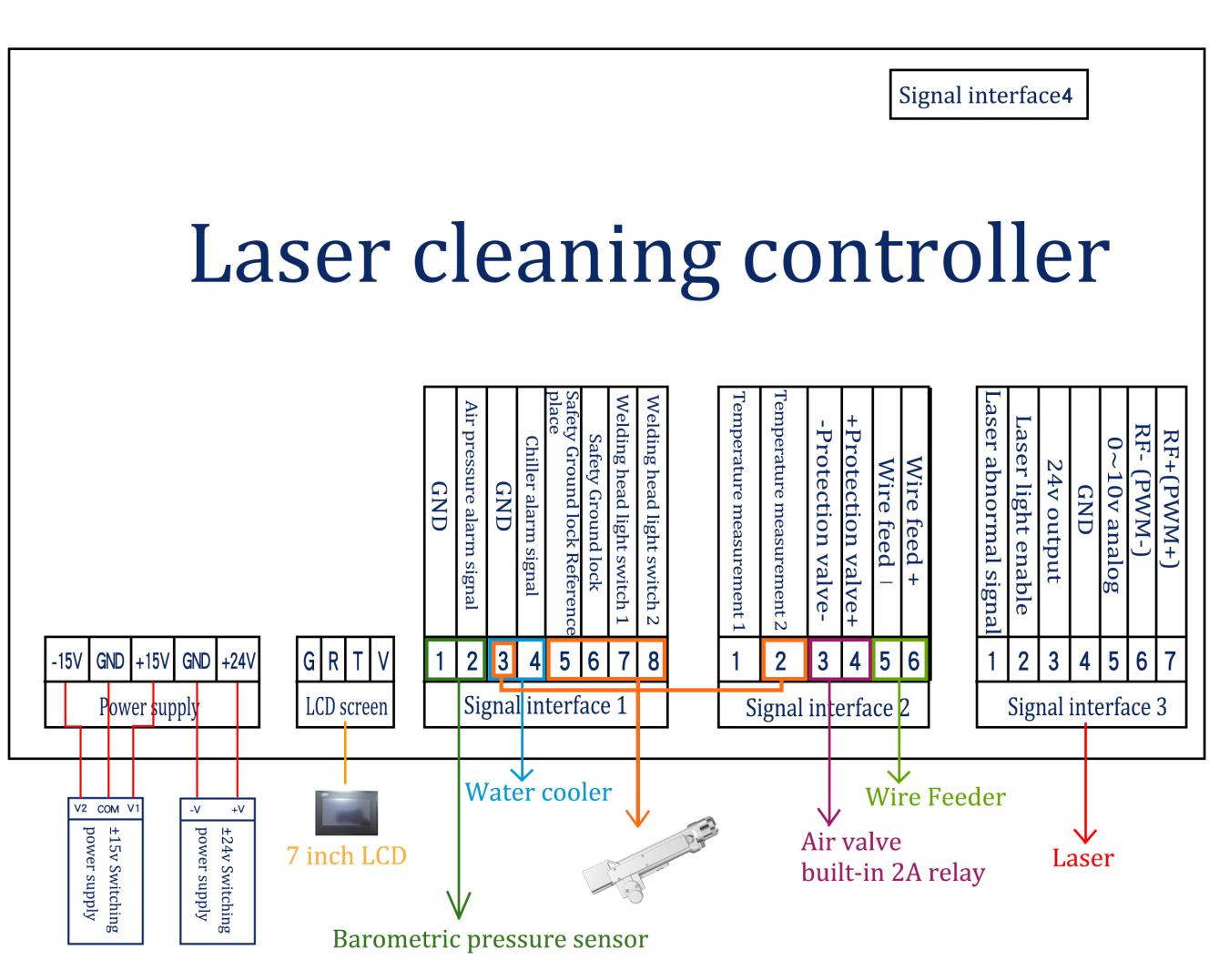

Inkcazo yocingo yomlawuli

| Iplagi | Ingcaciso | Uhlobo loMqondiso | Inkcazo eneenkcukacha | |

| Amandla | 1 | -15V | Ngena | I-V2 eqhagamshelwe kwi-15V yokutshintsha amandla ombane ibonelela nge-15V |

| 2 | GND | Indawo yereferensi | Qhagamshela kuyo nayiphi na i-COM ye-15V yokutshintsha unikezelo lwamandla | |

| 3 | +15V | Ngena | I-V1 eqhagamshelwe kwi-15V yokutshintsha umbane ibonelela nge-15V + | |

| 4 | GND | Indawo yereferensi | Qhagamshela kwi-V-of 24V yokutshintsha umbane | |

| 5 | +24V | Ngena | Qhagamshela kwi-V + ye-24V yokutshintsha unikezelo lwamandla | |

| Umhlaba womqondiso | 1 | G | Indawo yereferensi | Umhlaba wamandla |

| 2 | R | Umthumeli | Utshintshiselwano lwedatha | |

| 3 | T | Ukufumana isiphelo | Utshintshiselwano lwedatha | |

| 4 | V | Isiphumo | Imveliso 24V, kwaye ①bonelela nge-24V kuthotho lokubonisa izibuko | |

| Ujongano lomqondiso1 | 1 | GND | Indawo yereferensi | Umhlaba womqondiso |

| 2 | Uphawu lwe-alam yoxinzelelo lomoya | Ngena | I-Polarity inokusetwa kwi-interface yokuseta, isetelwe kwinqanaba eliphantsi xa ingasetyenziswa | |

| 3 | GND | Indawo yereferensi | Umhlaba womqondiso/Ucingo olumhlophe locingo olungundoqo oluntandathu oludityaniswe kwisidibanisi | |

| 4 | Uphawu lwe-alam yetanki yamanzi | Ngena | I-polarity inokumiselwa kwi-interface yokucwangcisa, ibekwe kwinqanaba eliphantsi xa ingasetyenziswa | |

| 5 | tshixa ngokukhuselekileyo indawo yesalathiso | Intambo etyheli yentsimbi emithandathu edityaniswe nesidibanisi | ||

| 6 | tshixa ngokukhuselekileyo | Intambo eluhlaza okwesibhakabhaka ye-6-core wire edityaniswe kwikhonkco | ||

| 7 | Ukuwelda intloko yokutshintsha ukukhanya | Ucingo olumnyama lwentsimbi emithandathu edityaniswe nesidibanisi | ||

| 8 | Ukuwelda intloko yokutshintsha ukukhanya | I-brown wire ye-6-core wire edityaniswe kwikhonkco | ||

| Ujongano loMqondiso 2 | 1 | Igciniwe | Igciniwe | Igciniwe |

| 2 | Umlinganiselo wobushushu | Intambo ebomvu yentsimbi emithandathu edityaniswe kwikhonkco | ||

| 3 | -Ivalve yegesi yokukhusela- | Indawo yereferensi | Umhlaba womqondiso, 2/4 ngumhlaba wesalathiso- | |

| 4 | +Ivalve yegesi yokukhusela + | Isiphumo | Imveliso ye-24V, yangoku> 2A, i-relay eyakhelwe-ngaphakathi, ngokuthe ngqo kwivalve yomoya | |

| 5 | -Ukutya ngocingo- | Wire feeder feed switch | ||

| 6 | +Ifidi yocingo+ | Wire feeder feed switch | ||

| Ujongano lomqondiso3 | 1 | Laser uphawu olungaqhelekanga | Ngena | Isignali ye-alam yeLaser |

| 2 | ILaser yenza ukuba+ | Isiphumo | +Laser vula + | |

| 3 | 24V | Isiphumo | 24V iphini yonikezelo lwamandla, imveliso xa umbane uvuliwe | |

| 4 | GND | Indawo yereferensi | Umhlaba wereferensi (yenza, iDA, umhlaba ekwabelwana ngawo oziimitha ezi-3) | |

| 5 | I-Analog+ | Isiphumo | Qhagamshela kubungakanani be-analog yelaser, DA+ | |

| 6 | -(PWM-) RF-(PWM-) | Isiphumo | Laser pulse ububanzi uphawu lokumodareyitha- | |

| 7 | +(PWM+) RF+(PWM+) | Isiphumo | I-Laser pulse modulation signal+ | |

Umlawuli wetheminali yonikezelo lwamandla

Ukunikezelwa kwamandla kusebenzisa i-interface ye-5P, kunye ne-24V enikezelwayo yokutshintsha umbane kunye ne-15V yokutshintsha umbane isetyenziselwa ukunikezelwa kwamandla.

Nceda uqaphele ukuba umbane we-15V wokutshintsha umbane ukwahlula izibonda ezilungileyo kunye nezibi, i-V1 ixhunyiwe kwi-15V +, i-V2 ixhunyiwe kwi-15V-, kwaye nayiphi na i-COM kwi-15V yokutshintsha umbane ixhunyiwe kwi-pin 2 GND!

Nceda uqaphele ukuba umbane wokutshintsha kufuneka usekelwe!

Umlawuli LCD24/5000

Intambo yeLCD ihanjiswa kunye nesixhobo kwaye inokudityaniswa ngokuthe ngqo.Jonga umfanekiso ongentla ngenkcazelo ethile

Ujongano lophawu lomlawuli 1

I-8P interface isetyenziswe ekupheleni kwe-interface ye-signal interface ye-1 ukulungiselela umqondiso

①/②iphini luphawu lokufaka ialam yoxinzelelo lomoya.Ukuba kufuneka ivulwe (i-wiring iyadingeka), nceda usethe inqanaba le-alamu yoxinzelelo lomoya ukuya phezulu ngasemva, kungenjalo iphantsi.

③/④ isikhonkwane sisixhobo somqondiso wetanki yamanzi.Ukuba kufuneka ivulwe (i-wiring iyafuneka), nceda usethe inqanaba le-alam yetanki yamanzi ukuya phezulu ngasemva, kungenjalo iphantsi.

Nceda uqaphele ukuba nayiphi na enye ye-① / ③ iqhagamshelwe kumgca omhlophe we-Six core wire ye-welding joint.

⑤ iqhagamshelwe kumgca otyheli we-Six core wire ye welding joint.

I-⑥ iqhagamshelwe kumgca ozuba weNtathu yocingo olungundoqo lwe-welding joint.

⑦ idityaniswe kumgca omnyama we-Six core wire ye-welding joint.

⑧ sisixhobo sokutshintsha ukukhanya kwejoyinti yewelding, edityaniswe kumgca omdaka wentsimbi emithandathu yocingo olungundoqo lwe-welding joint.

Ujongano lwesiginali yomlawuli 2

I-6P interface isetyenziswe ekupheleni kwe-signal interface ye-2 yevalve yomoya kunye nokutya kocingo

①Bekelwe bucala.

②umlinganiselo wobushushu, odityaniswe kumgca obomvu we-6-core wire ye-welding joint.

I-③/④pin yi-24V yokuphuma kwevalve yomoya, kwaye ibhodi yokulawula ine-relay eyakhelweyo, enokuthi idibaniswe ngokuthe ngqo kwivalve yomoya.

⑤/⑥Ibekelwe.

Ujongano lwesignali yomlawuli 3

①I-Pin luphawu lwe-alaser igalelo +, ukuba ufuna ukuyenza, nceda usete inqanaba loxinzelelo lomoya phezulu ngasemva.

②Iphini iyasebenza+, qhagamshela kwilaser yenza+

③Iphini yi 24V imveliso, imveliso ngqo 24V+ emva kombane

④Inombolo yesilo-qabane ngumhlaba oqhelekileyo (umhlaba wereferensi yeenyawo 1/2/3/5)

⑤I-pin yenombolo yi-analog quantity + output, ubuninzi be-analog bunikiwe

⑥I-Pin yi-PWM-modulated signal

⑦Iphini lenombolo yiPWM+ isignali yokumodareyitha

Umzobo wocingo lomlawuli

Qaphela: Ucingo oluphantsi lombane otshintshayo kufuneka lusekelwe ngokufanelekileyo!

Ujongano lwegalelo lokubona

Intloko yokuwelda i-SUP ifanelekile kuninzi lweejeneretha ze-laser zamashishini.Izixhumi zefiber optical ezisetyenziswa ngokuqhelekileyo ziquka i-IPG, i-Ruike, i-Chuangxin, i-Fibo, i-Tottenham, i-Jept, i-Kaplin, njl njl. I-opticals kufuneka igcinwe icocekile kwaye lonke uthuli kufuneka lususwe ngaphambi kokusetyenziswa.

Xa i-fiber ifakwe, intloko yokusika kufuneka ijikelezwe ngama-degrees angama-90 ukuba i-horizontal, kwaye emva koko i-fiber isetyenziselwa ukukhusela uthuli ekuweleni kwi-interface.

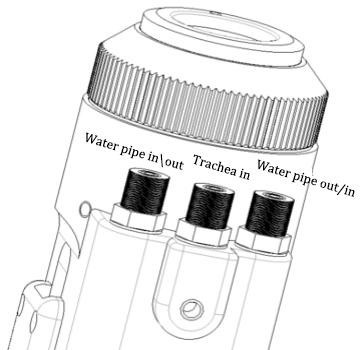

Ukhuselo lwegesi kunye ne-water chiller interface

Umbhobho wamanzi kunye ne-interface yombhobho womoya unokufakwa kunye ne-hoses kunye nobubanzi obungaphandle be-6MM kunye nobubanzi obungaphakathi be-4MM.Indlela yomoya ingena embindini, kwaye la macala mabini yimibhobho yaManzi yokungena nokuphuma (kungakhathaliseki icala lendawo yokungena nokuphumayo), Njengoko kubonisiwe ngezantsi:

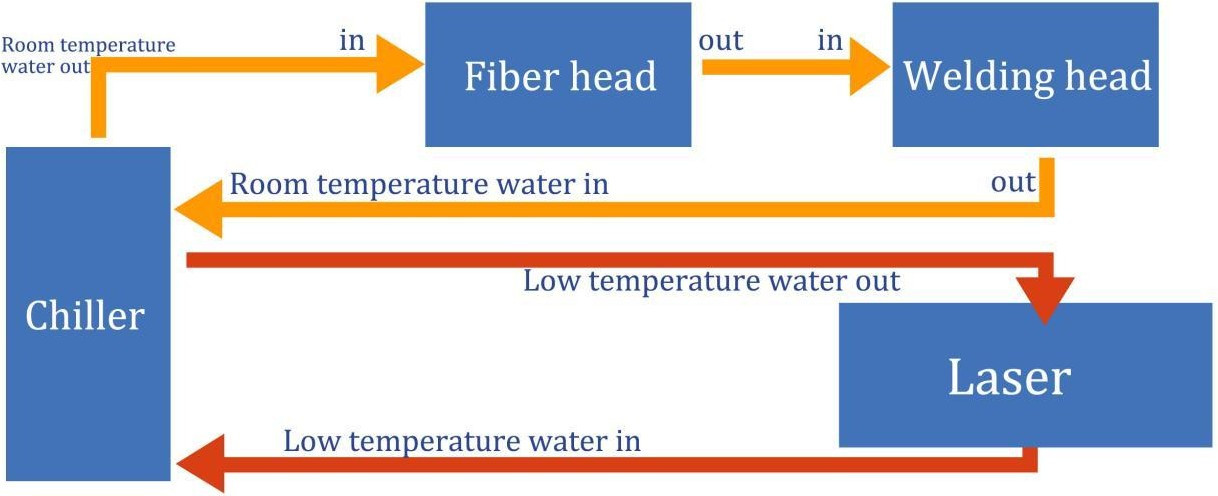

Inkqubo yokupholisa yahlulwe kwisiphaluka samanzi inxalenye yentloko ye-welding kunye nenxalenye yesiphaluka samanzi yentloko ye-fiber optical, edityaniswe kuluhlu, njengoko kuboniswe kumzobo ongezantsi:

Ukucoca umpu kunye nojongano lwebhokisi yolawulo

Iingcingo ezintathu zisetyenziselwa ukudibanisa umpu wokucoca kunye nebhokisi yokulawula, kubandakanywa iingcingo ezimbini zamandla emoto, iingcingo ezintlanu zesignali yemoto kunye nezikhonkwane ezintandathu zesignali.

2.51.Amandla enjini / iingcingo zomqondiso (ezimbini ezimnyama) ziqhagamshelwe ngokuthe ngqo kwinxalenye yemoto yejoyinti yewelding kwaye inokususwa (iindlela ezimbini: 1. Vula isigqubuthelo semoto kunye nepleyiti esecaleni yompu obanjwa ngesandla; ibhokisi yolawulo, zombini ziplagi)

2.52.Ikona yentsimbi engundoqo emithandathu isebenzisa iplagi yasemoyeni ekhutshwayo

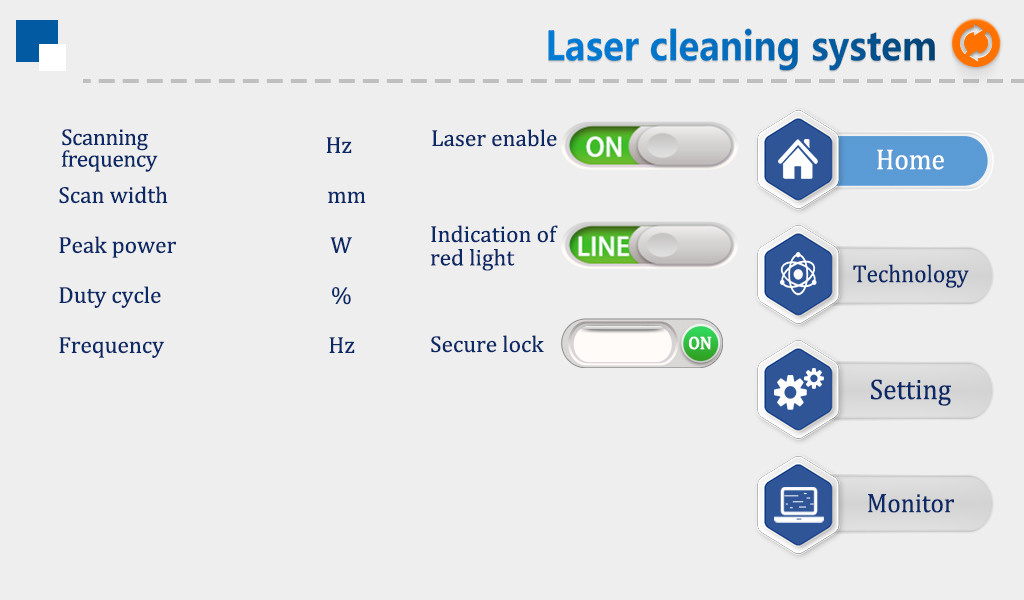

Ikhaya leP1-1, Khanyisa

①Kolu jongano, ungabona inkqubo yangoku yeeparameters (inkqubo ayinakuguqulwa kweli phepha) kunye nolwazi lwexesha lokwenyani.

②Kumandla akwimo, usetyenziso LUVULIWE ngokungagqibekanga, kwaye isibane esibomvu YI LINE ngokungagqibekanga.

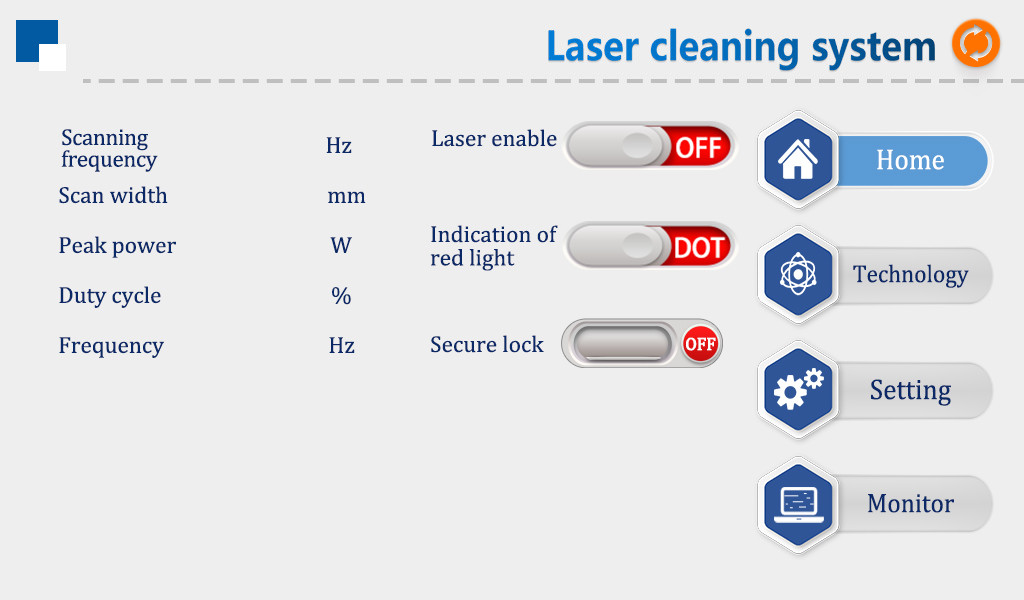

Xa i-access icinyiwe, "cima" ibonisiwe, kwaye isignali yokuvumela ayiyi kuthunyelwa kwi-laser, enokuthi isetyenziswe ukuvavanya umsebenzi wokuphuma komoya.

Cima isalathiso sesibane esibomvu, bonisa "ichaphaza", kwaye injini iyeke ukujinga.Ngeli xesha, ukukhanya okubomvu kuyingongoma yokulungelelanisa iziko

③”Isitshixo sokhuseleko”,Xa “isitshixo sokhuseleko” somzimba wompu sivulwa, siboniswa njengohlaza “sivuliwe” kwaye sinokukhupha ukukhanya ngokwesiqhelo.Xa ivaliwe, ibomvu "cimile" kwaye ayikwazi ukuvelisa ukukhanya.

P1-2 Ekhaya, Cima

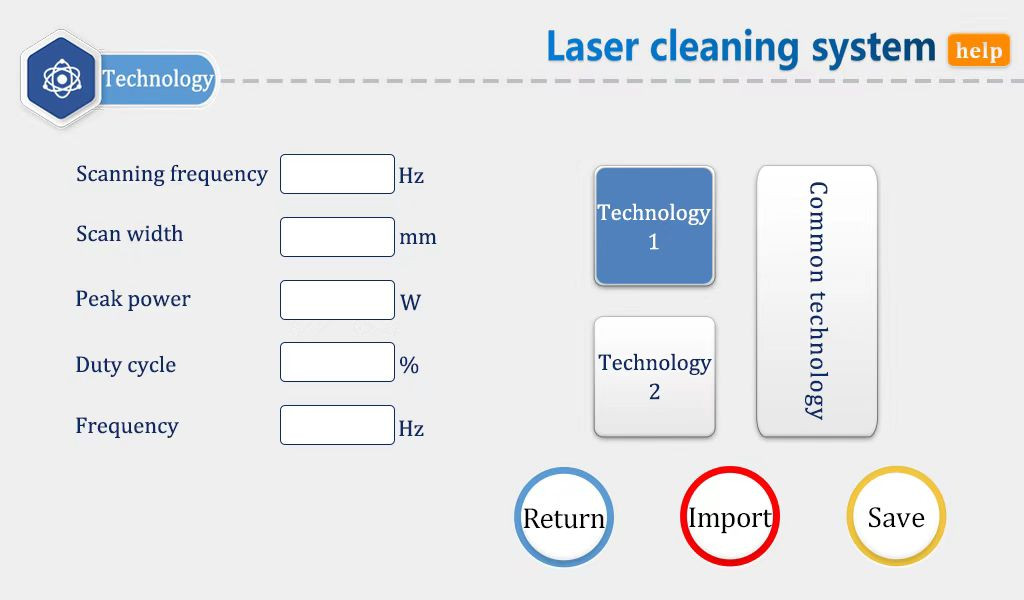

P2 inkqubo interface

①Ujongano lwenkqubo luqulathe iiparamitha zenkqubo yokugunyazisa.Cofa ibhokisi (ebomvu) ukuziguqula.Emva kohlengahlengiso, cofa u-Kulungile, kwaye emva koko uzigcine kwinkqubo enqumlayo.Xa isetyenziswa, cofa ngaphandle (lungisa ukugcina ngaphandle).

②Uluhlu lwefrikhwensi yokuskena yi-10-100Hz kwaye ububanzi bokuskena yi-0 ^ 300mm. (esona santya sisetyenziswa kakhulu sokuskena yi-50Hz kwaye ububanzi yi-300mm.Nceda uqaphele ukuba obu bubanzi kufuneka buhambelane nogxininiso lwakho.).

③ Amandla encopho ayakuba ngaphantsi okanye alingane namandla elaser kwiphepha leparameter (ukuba amandla elaser angama-1000W, eli xabiso aliyi kuba phezulu kune-1000).

④Uluhlu lomjikelo womsebenzi: 0 ~ 100 (engagqibekanga: 100, ngokuqhelekileyo akukho mfuneko yokutshintsha).

⑤Uluhlu lwe-pulse frequency lunconywa ukuba lube yi-5-5000Hz (i-default yi-2000, ngokuqhelekileyo ayifuni ukuguqulwa).

⑥Cofa iqhosha loncedo phezulu ekunene ukuze ufumane ingcaciso yeeparamitha ezifanelekileyo.

⑦Emva kokuguqula iiparameters, ungajonga ukuba ungeniso luphumelele na kwiphepha lasekhaya.

⑧ Jonga inkqubo kwiapplet.

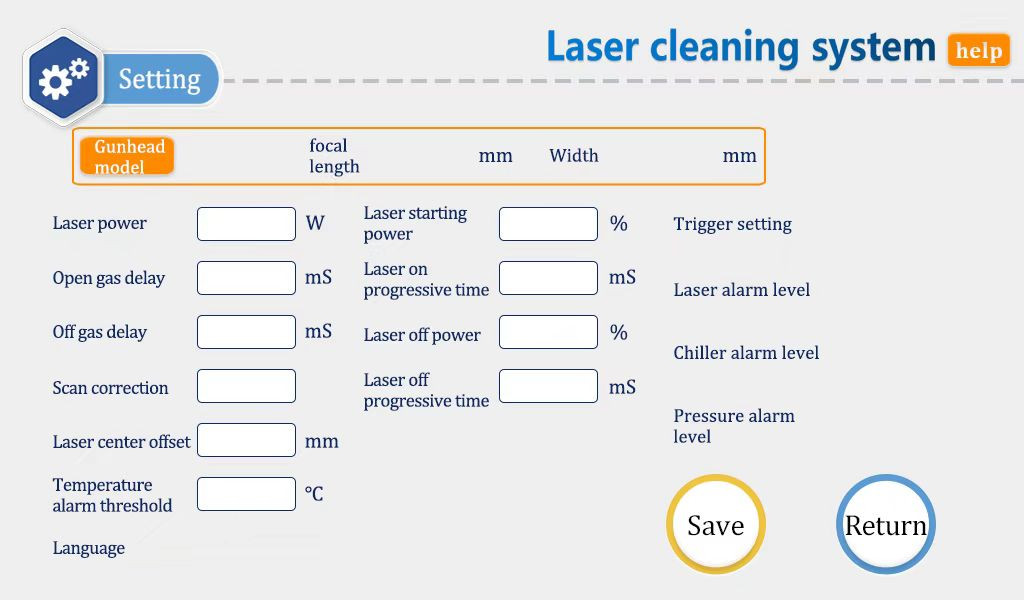

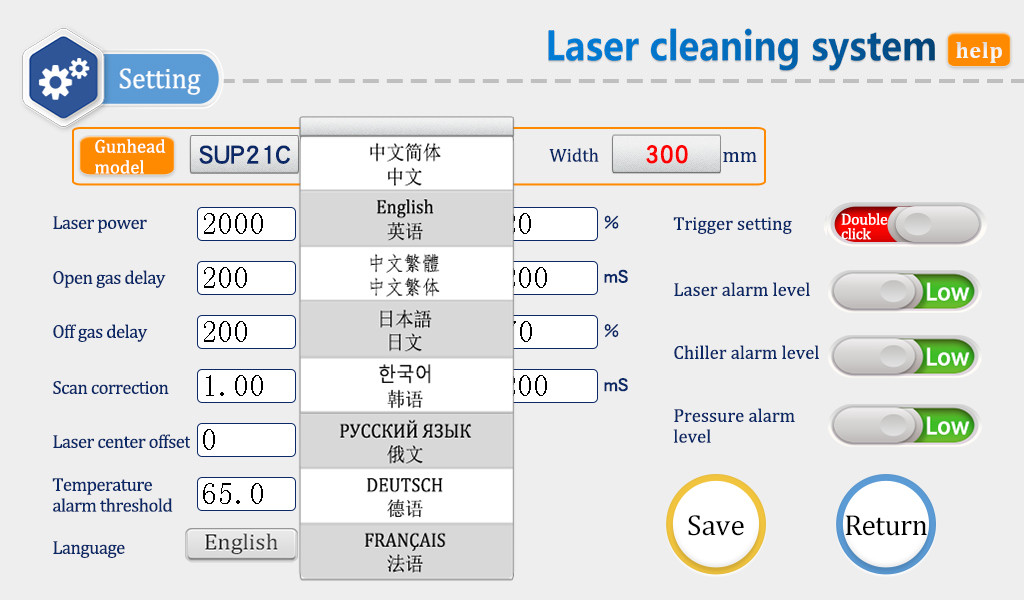

P3-1 Setting interface

Ngenisa igama lokugqitha 123456 ukungena kolu jongano

① Amandla e-laser ngamandla e-laser asetyenzisiweyo, nceda ugcwalise ngokuchanekileyo.

②Ukulibaziseka kokutshintsha igesi yi-200ms ngokungagqibekanga, kwaye uluhlu luyi-200ms-3000ms.

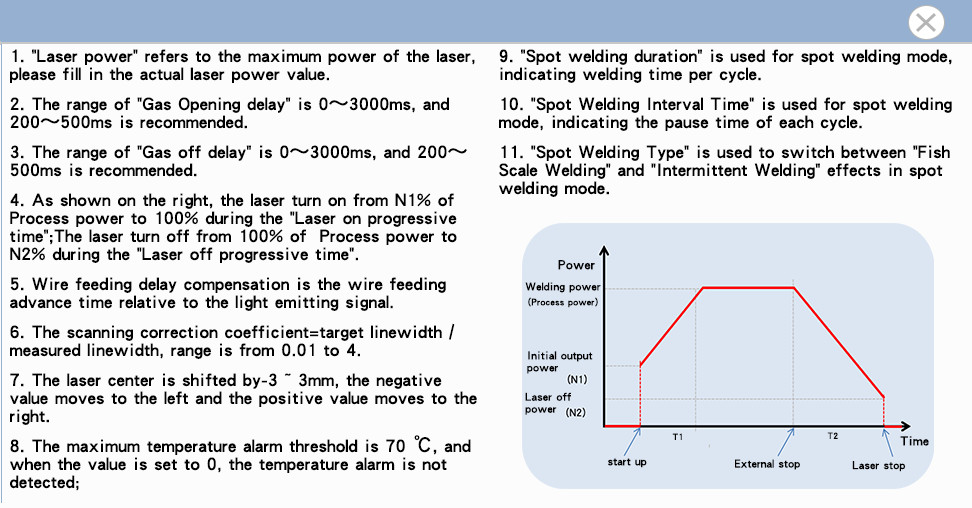

③Xa isibane silayitiwe, sinyuka kancinci ukusuka kwi-N1% yamandla enkqubo ukuya kwi-100%;Xa ukukhanya kucinyiwe, kuncipha ngokuthe ngcembe ukusuka kwi-100% yamandla enkqubo ukuya kwi-N2;(njengoko kubonisiwe kulo mfanekiso ungezantsi).

P3-2 Ukuseta ujongano, ukucaciswa kwepharamitha

④ Ngokubanzi, ukuguqulwa kwamandla optical yi-20% kunye nexesha eliqhubekayo lokutshintsha liyi-200ms.

⑤Iqondo eliphezulu le-alarm threshold yi-65 ℃.Xa eli xabiso limiselwe kwi-0, i-alamu yeqondo lokushisa ayiyi kufunyanwa.

⑥Skena uluhlu lwe-coefficient yokulungiswa kwe-0.01 ~ 4, i-coefficient yobubanzi bomgca wethagethi / ububanzi bomgca olinganisiweyo: ukungagqibeki ngu-1.0.

⑦ Iziko le-laser lihlanjululwe ngu-75 ~ 75mm, elihla liye ekhohlo kwaye linyuke ukuya ngasekunene.Kufuneka isetyenziswe ukulungelelanisa iziko lokukhanya okubomvu.

⑧Inqanaba le-alarm yomgangatho woxinzelelo lomoya / i-cooler yamanzi / i-laser iphantsi ngokungagqibekanga.Xa usebenzisa lo mqondiso we-alamu, ukuba i-alamu yoxinzelelo lomoya yangaphandle ifakiwe, iya kutshintshwa kwinqanaba eliphezulu, ngaphandle koko i-alamu engaqhelekanga iya kubonakala, kunye nezinye iimpawu ze-alamu ziyafana.

⑨ Cofa iqhosha elithi "isiTshayina" ukutshintshela kwezinye iilwimi kwikholamu yokukhetha ulwimi.Okwangoku, inguqulelo eqhelekileyo ixhasa iilwimi ezisibhozo: isiTshayina esenziwe lula, isiTshayina esiNtu, isiNgesi, isiJapan, isiKorea, isiRashiya, isiJamani kunye nesiFrentshi.Ukuba ufuna ezinye iinguqulelo zeelwimi, nceda uqhagamshelane nathi.

P3-3 Ukuseta interface-ulwimi iswitshi

⑩Eli phepha liphepha loncedo lwephepha lokucwangcisa.Cinezela ixesha elide "ukubuyisela useto lwefektri" imizuzwana emi-3 ukubuyisela zonke iiparameters zokumisela "kwifactory parameters".Cinezela ixesha elide "gcina njengesetingi zasefektri" imizuzwana emi-3 ukuseta iiparamitha zokuseta zangoku kwi "factory parameters".

P3-4 Ukucwangcisa ujongano-uncedo

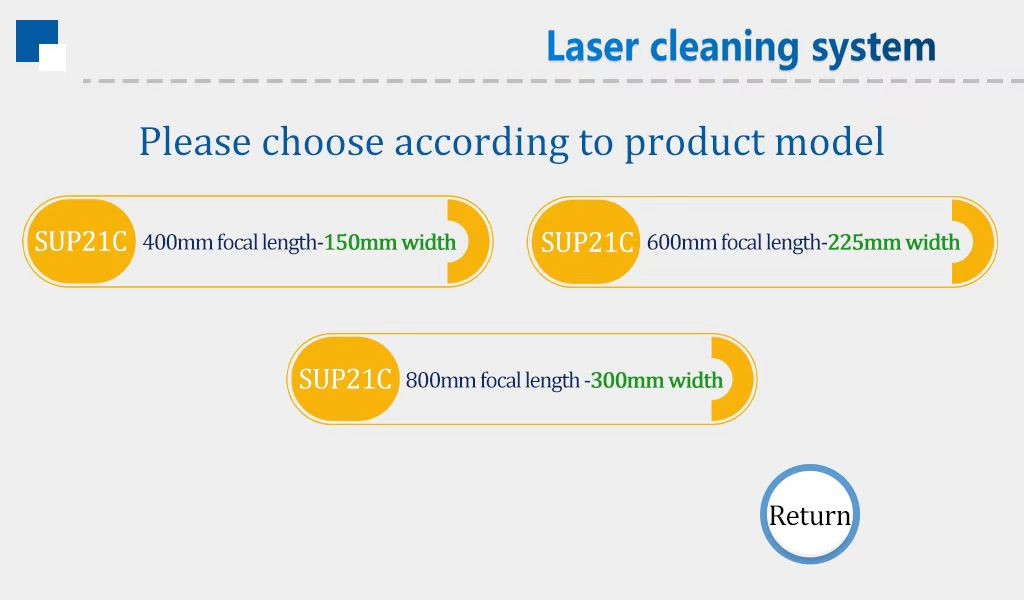

Cofa indawo "yemodeli yentloko yompu" ukukhetha ububanzi bokuskena obuhambelana nokwahlukileyo

P3-5 Ukuseta ujongano-tshintsha phakathi kobude obahlukeneyo bokujolisa

P4 Monitor ujongano

Eli phepha libonisa ubume kunye nolwazi lwesixhobo sophawu ngalunye

I-Laser trigger signal: le meko iyatshintsha ukusuka kwengwevu ukuya eluhlaza emva kokutsala i-trigger.

I-Laser / i-cooler yamanzi / i-alamu yoxinzelelo lomoya: jonga isethi yayo ephezulu kunye namanqanaba aphantsi.

Umqondiso wemveliso uboniswa embindini wephepha.Xa umqondiso uphuma, ungwevu kwaye uluhlaza.

Ugunyaziso lwezixhobo: unokugunyazisa ixesha lokusetyenziswa kwesixhobo.Xa isixhobo sisetyenziselwa ixesha elingaphezu kwexesha elibekiweyo, ugunyaziso luya kupheliswa.

Ukucima ixesha: cofa "ugunyaziso lwesixhobo", faka "FFFFFFBB001" kwiphepha lokugqitha ukuze uqalise ixesha, faka "FFFFFFBB000" ukucima idatha kunye nokumisa ixesha.

Uguqulelo lwenkqubo: amaqela amathathu amanani.Iqela lokuqala liyinguqulo ye-hardware, iqela lesibini yinkqubo yeprogram ye-MCU, kwaye iqela lesithathu yinguqulo yesikrini sokuchukumisa.

P4 ujongano lokuxilongwa

Cofa iqhosha elithi "ukuxilongwa" ukufaka iphepha lokuxilongwa. Kweli phepha, i-laser ayiyi kukhupha ukukhanya.Unokuzimela ngokuzimeleyo "PWM", "i-laser yenza", "ivalve yomoya yenza" kunye "nobungakanani be-analog" ngo "switch control".Thelekisa ixabiso elifunyenweyo kunye nexabiso lethiyori ukugweba ukuba umsebenzi webhokisi yokulawula uqhelekileyo.

Ukugcinwa kunye neendlela zokutshintsha iilensi zokukhusela:

①Phambi kotyando, hlamba izandla zakho ngesicoci kwaye uzomise, kwaye wosule izandla zakho kwakhona ngomqhaphu oncanyathiselwe utywala.

② Susa izikhonkwane zesigqubuthelo selensi ekhuselayo kwindawo engenathuli, khupha i-lens yokukhusela, uyikhusele (egqunywe ngephepha lokufihla), kwaye ukhangele i-lens yokukhusela (ukuba kukho indawo evuthayo ecacileyo phezu kwendawo yokukhusela. ilens, kufuneka itshintshwe ngokuthe ngqo.)

③ Emva koko jonga umsesane wokutywina wogcino lwamandla amhlophe phantsi kwelensi ekhuselayo.(ukuba iringi ye-accumulator seal ikrwelwe okanye ikhubazekile, ayinakusetyenziswa kwaye kufuneka itshintshwe ngoko nangoko.

④Sula indawo yokuvula kunye nengaphakathi lendawo yokugcina impahla ngebhola yomqhaphu efakwe etywaleni, khawuleza ufake inkxaso yesipili esikhuselayo kwindawo yokugcina isipili, kwaye utshixe izikrufu.

Ngokukhawuleza i-laser / i-cooler yamanzi / i-alamu yoxinzelelo lomoya

① Ukuba le alamu ingentla yenzeka ngaphandle kokusebenzisa isignali ye-alam, nceda utshintshe inqanaba le-alam.

②Ukuba i-alamu engentla iyenzeka xa i-alamu isetyenzisiwe, khangela ukuba i-alamu yezixhobo ezihambelanayo okanye amanqanaba aphezulu kunye aphantsi ophawu lwe-alamu abekwe ngendlela engalunganga.

Isikrini asikhanyiswanga / akukho mpendulo xa ucofa

①Isikrini asisebenzi.ukuba umlawuli unikwe amandla (ifeni iyasebenza), khangela ukuba iingcingo ezine ezingundoqo phakathi kwesilawuli kunye nekhusi zifakwe ngokuchanekileyo kwaye ingaba i-24V yombane yepini yokuqala kunye nephini yesine iqhelekile.

②Ukuba unqakrazo aluphumeleli ngexesha lokusetyenziswa okuqhelekileyo, khangela ukuba umatshini wonke ubangelwa ukushisa okuphezulu kakhulu.

③Nqakraza intshukumo ayinakungenwa,Jonga ukuba iingcingo ezine ezingundoqo phakathi komlawuli kunye neskrini zifakwe ngokuchanekileyo, nokuba iphini yesibini kunye nephini lesithathu ziqhelekile,Jonga i-2.1.2 LCD yesilawuli ngeenkcukacha

④Akukho mpendulo xa ucofa izixhobo ezisanda kufakwa.Kungenzeka ukuba uguqulelo lwesixokelelwano aluhambelani.Yibrashi nje inkqubo kwakhona.Kwikhadi le-SD, nceda ubuze inkampani yethu

Ukuyeka ngokukhawuleza ukukhanya ngexesha lokucubungula

Jonga ukuba iqhosha le-trigger kunye nezinye ii-alam ziqhelekile kujongano lojongano

Isigaba sesithathu sonikezelo lwamandla ombane wokusetyenziswa komatshini we-laser welding

Qaphela: unikezelo lwamandla lwesigaba ezibini okanye ezithathu luxhomekeke kunikezelo lwamandla olufunwa yilaser kunye ne chiller, hayi ubungakanani bokubopha.

Iimpawu eziphambili: Inkqubo yokulawula ukuziphuhlisa, ii-alamu ezininzi zokhuseleko, ubungakanani obuncinci, ukusebenza okuguquguqukayo kunye nokulula ukuyisebenzisa.

Izinzile ngakumbi: Zonke iiparameters ziyabonakala, ukujonga ixesha langempela kwimeko yomatshini wonke, ukuphepha iingxaki kwangaphambili, kulula ngakumbi ukulungisa iingxaki kunye nokusombulula iingxaki, ukuqinisekisa ukusebenza okuzinzile kwentloko ye-welding.

Inkqubo: Zonke iiparamitha ziyabonakala, umgangatho wokucoca uphelele ngakumbi.

Iiparamitha ezizinzileyo kunye nokuphindaphinda okuphezulu: uxinzelelo lomoya we-nozzle kunye ne-lens state, nje ukuba amandla e-laser azinzile, iiparitha zenkqubo kufuneka ziphindwe.Ukuphucula kakhulu ukusebenza kakuhle, ngelixa kuncitshiswa neemfuno zabaqhubi.