i-handheld laer welding head factory

Umzi-mveliso wentloko we-laer welding ephathwayo,

edumileyo ephathwayo laser welding intloko, laser welding gun umenzi, laser welding intloko imveliso, ukuwelda intloko kumazwe angaphandle, intloko ye-wholesale laser welding,

Ikhuselekile.– Ekhuselekile

Uphando oluzimeleyo kunye nophuhliso lwenkqubo yokukhangela ukhuseleko, ukuseta inani lee-alamu zokhuseleko, ukhuseleko kunye nokuzinza

Ukugcina ixesha - ngokufanelekileyo kwaye kulula

Isibuko sokujolisa, idrowa yesipili sokukhusela, indawo efanelekileyo

Ukukhanya - Ukukhanya kunciphisa umthwalo

Ubungakanani obuncinci, ubunzima obulula, ukusebenza okuguquguqukayo, kulula ukuyisebenzisa

Umgangatho - i-welding enhle - ukusebenza okuzinzileyo

Amandla aphezulu e-welding, i-deformation encinci, ubunzulu bokunyibilika okuphezulu

Ukusebenza - Iimpawu ezininzi

Inkxaso ebambe ngesandla i-welding eqhubekayo, ukuwelda, ukucoca, ukusika, "isandla" "ukususela" - umzimba, ukugunyazwa kwephasiwedi

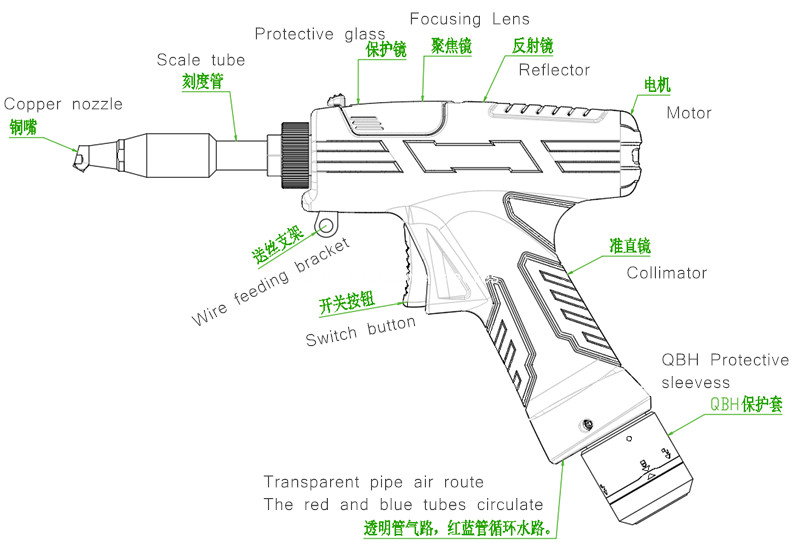

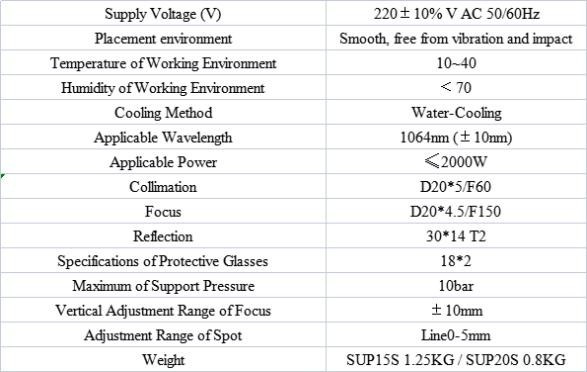

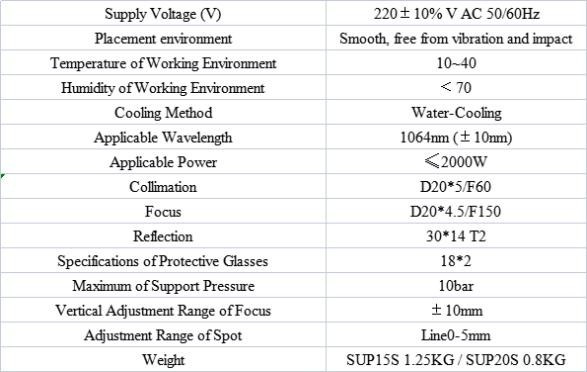

Intloko ye-welding ephezulu i-handheld welding cut head eqaliswe ngo-2019. Imveliso igubungela izibhamu ze-welding ezibanjwe ngesandla kunye neenkqubo zokulawula eziziphuhlisileyo, kwaye zixhotyiswe ngama-alamu amaninzi okhuseleko kunye namandla asebenzayo akhuselekileyo kunye nezicwangciso zokukhanya.Le mveliso inokutshintshwa kwiintlobo ezahlukeneyo ze-fiber lasers;i-optical optical kunye noyilo olupholileyo lwamanzi luvumela intloko ye-laser ukuba isebenze ngokuzinzileyo ixesha elide phantsi kwe-3000W.

1) Qinisekisa ukusekwa okuthembekileyo phambi kokunikezelwa kombane.

2) Intloko ye-laser output idibaniswa nentloko ye-welding.Nceda ujonge intloko yemveliso ye-laser ngononophelo xa usebenzisa ukuthintela uthuli okanye olunye ungcoliseko.Xa ucoca intloko ye-laser output, nceda usebenzise iphepha elikhethekileyo lens.

3) Ukuba isixhobo asisetyenziswanga ngokuhambelana neendlela ezichazwe kule ncwadana, sinokuthi sisebenze ngokungaqhelekanga kwaye sibangele umonakalo.

I-4) Xa utshintsha i-lens yokukhusela, nceda uqinisekise ukuba uyayikhusela.

5) Nceda uqaphele: Xa usebenzisa okokuqala, xa ukukhanya okubomvu kungenakuphuma emlonyeni wobhedu, qiniseka ukuba awukhuphi ukukhanya.

Ipakethi yokuhanjiswa kweenkcukacha

Iinkcukacha zokuziswa kwephakheji ye-welding ebambe ngesandla

★ Umaleko wokuqala

SUP20S intloko welding 1pc

Inkqubo 1 iseti

Inkqubo yentambo yomgangatho we-10m

★ Umaleko wesibini

Umbhobho wobhedu 7pcs Ukusika umbhobho 1pc

Isikali ityhubhu 1pc

I-lens yokukhusela i-10pcs

I-Ground clamp 1pc

Intambo yoqhagamshelo lwesikrini 1m

Bonisa iqhosha lesikrini 1seti

Umaleko wesithathu

Bonisa isikrini 1pcs

utshintsho ower 2pcs

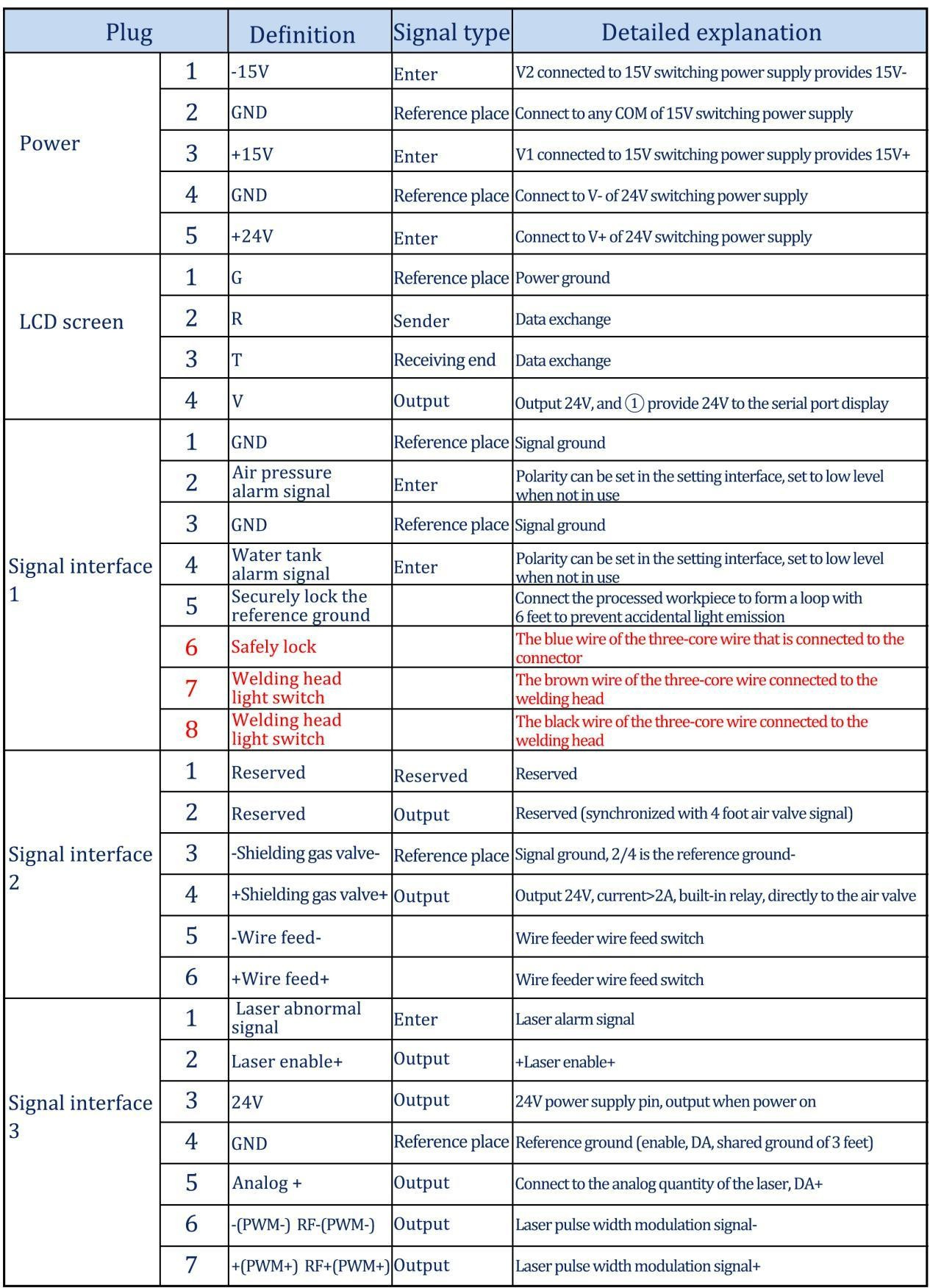

Inkcazo yocingo yomlawuli

Umlawuli wetheminali yonikezelo lwamandla

Unikezelo lwamandla lusebenzisa i-interface ye-5P, kwaye unikezelo lwamandla okutshintsha kwe-24V kunye nokunikezelwa kombane okutshintshwa kwe-15V kusetyenziselwa ukubonelela ngombane.

Nceda uqaphele ukuba umbane we-15V wokutshintsha umbane ukwahlula izibonda ezilungileyo kunye nezibi, i-V1 ixhunyiwe kwi-15V +, i-V2 ixhunyiwe kwi-15V-, kwaye nayiphi na i-COM kwi-15V yokutshintsha umbane ixhunyiwe kwi-pin 2 GND!

Nceda uqaphele ukuba umbane wokutshintsha kufuneka usekelwe!

Umlawuli LCD24/5000

Intambo yeLCD ihanjiswa kunye nesixhobo kwaye inokudityaniswa ngokuthe ngqo.Jonga umfanekiso ongentla ngenkcazelo ethile

Umlawuli LCD24/5000

Intambo yeLCD ihanjiswa kunye nesixhobo kwaye inokudityaniswa ngokuthe ngqo.Jonga umfanekiso ongentla ngenkcazelo ethile

Ujongano lophawu lomlawuli 1

①/②Iphini luphawu loxinzelelo lomoya lokungenisa, ukuba ufuna ukwenza (ucingo olufunekayo), nceda usete inqanaba le-alam yoxinzelelo lomoya ngasemva phezulu, kungenjalo iphantsi.

I-③/④ isikhonkwane sisixhobo somqondiso wetanki yamanzi.Ukuba ufuna ukuyenza (i-wiring iyafuneka), nceda useta inqanaba le-alam yoxinzelelo lomoya ngasemva liphezulu, kungenjalo liphantsi.

⑤I-pin yenombolo ngumhlaba wesalathiso wokutshixa umhlaba wokhuseleko, kwaye iqhagamshelwe ngokuthe ngqo kwisixhobo sokusetyenzwa ngocingo.

⑥ Hayi isikhonkwane sisitshixo somhlaba wokhuseleko wentloko ye-welding, eqhagamshelwe kwintambo eluhlaza okwesibhakabhaka yocingo oluthathu olungundoqo, xa intloko ye-welding ichukumisa i-workpiece, isitshixo sokhuseleko sivuliwe ngeli xesha.

⑦ I-pin yenombolo sisitshixo sentloko yokuwelda, eqhagamshelwe kwintambo emdaka yocingo olungundoqo oluthathu.

⑧Inombolo yePin sisitshixo sokukhanya sentloko ye-welding, eqhagamshelwe kucingo olumnyama lwe-three-core wire, xa i-trigger itsalwa, iqhosha lokuqalisa livuliwe.

Nceda uqaphele ukuba kuphela xa kungekho alamu, kwaye umqondiso wokutshixa okukhuselekileyo kunye neqhosha le-trigger livuliwe, isignali yemveliso ye-port elandelayo iya kuthunyelwa ngaphandle.

Ujongano lwesiginali yomlawuli 2

Ukuphela kwe-2 ye-interface ye-signal interface isebenzisa i-interface ye-6P, kwaye i-valve yomoya inxulumene nokutya kocingo

①Iinyawo ezigciniweyo

②Iinyawo ezigciniweyo (zilungelelaniswe ne-4-pin signal)

③/④Unyawo yivalve 24V ephumayo, qhagamshela kwivalve

⑤/⑥Iphini luphawu lwengcingo yesixhasi socingo, isibuko somqondiso we-wire feeder, nokuba ilungile okanye ingalunganga.

Ujongano lwesignali yomlawuli 3

①I-Pin luphawu lwe-alaser igalelo +, ukuba ufuna ukuyenza, nceda usete inqanaba loxinzelelo lomoya phezulu ngasemva.

②Iphini iyasebenza+, qhagamshela kwilaser yenza+

③Iphini yi 24V imveliso, imveliso ngqo 24V+ emva kombane

④Inombolo yesilo-qabane ngumhlaba oqhelekileyo (umhlaba wereferensi yeenyawo 1/2/3/5)

⑤I-pin yenombolo yi-analog quantity + output, ubuninzi be-analog bunikiwe

⑥I-Pin yi-PWM-modulated signal

⑦Iphini lenombolo yiPWM+ isignali yokumodareyitha

Umzobo wocingo lomlawuli

Qaphela: I-terminal ye-COM ye-±15V yokutshintsha umbane kunye ne--V (0V) i-terminal ye-+24V yokutshintsha umbane kufuneka iqhagamshelwe kwi-GND kwaye iqhagamshelwe ngokupheleleyo kwi-workpiece ngexesha elinye.Igobolondo yombane wokutshintsha kufuneka idityaniswe phantsi, ngaphandle koko, i-alarm yokhuseleko lomhlaba inokuthi yenzeke, kwaye akukho kukhanya kuya kukhutshwa.

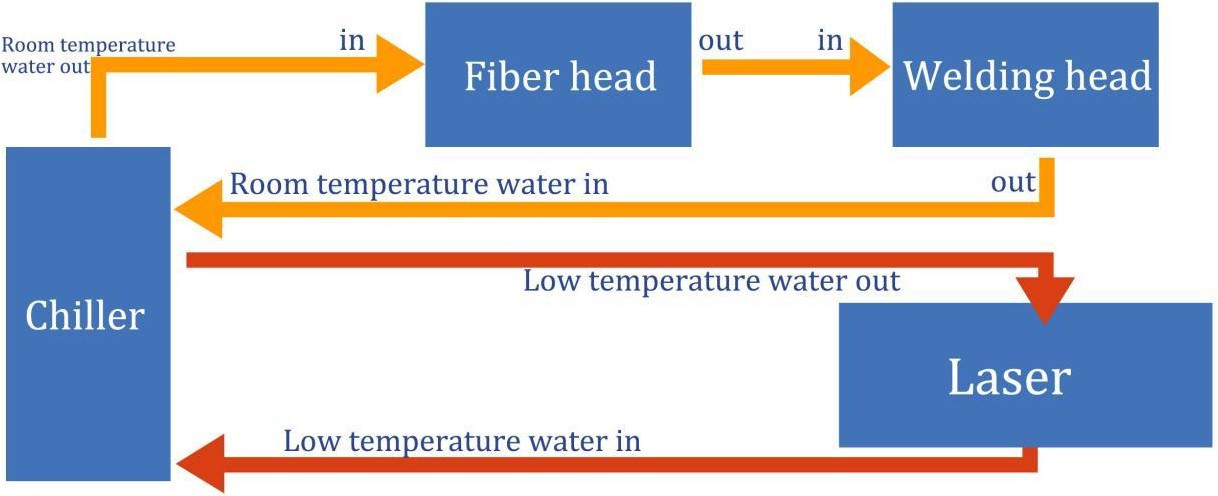

Ujongano lwegalelo lokubona

Intloko yokuwelda i-SUP ifanelekile kuninzi lweejeneretha ze-laser zamashishini.Izixhumi zefiber optical ezisetyenziswa ngokuqhelekileyo ziquka i-IPG, i-Ruike, i-Chuangxin, i-Fibo, i-Tottenham, i-Jept, i-Kaplin, njl njl. I-opticals kufuneka igcinwe icocekile kwaye lonke uthuli kufuneka lususwe ngaphambi kokusetyenziswa.

Xa i-fiber ifakwe, intloko yokusika kufuneka ijikelezwe ngama-degrees angama-90 ukuba i-horizontal, kwaye emva koko i-fiber isetyenziselwa ukukhusela uthuli ekuweleni kwi-interface.

indlela yokufaka (iiApplets)

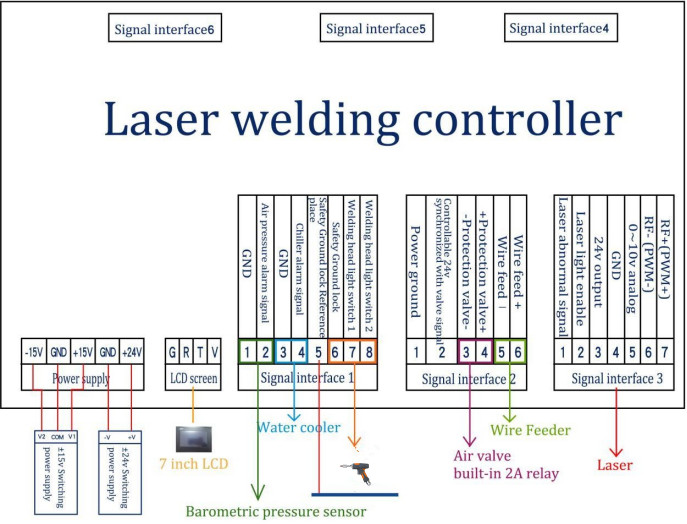

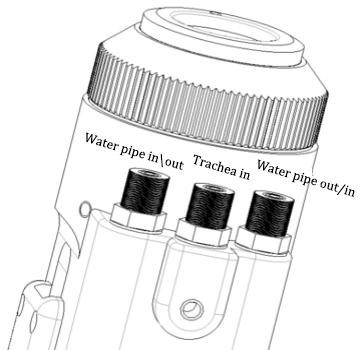

Ukhuselo lwegesi kunye ne-water chiller interface

Umbhobho wamanzi kunye ne-interface yombhobho womoya unokufakwa kunye ne-hoses kunye nobubanzi obungaphandle be-6MM kunye nobubanzi obungaphakathi be-4MM.Indlela yomoya ingena embindini, kwaye amacala amabini yimibhobho yokungena nokuphuma kwamanzi (kungakhathaliseki icala lendawo yokungena nokuphumayo) , Njengoko kubonisiwe ngezantsi:

Inkqubo yokupholisa yahlulwe kwisiphaluka samanzi inxalenye yentloko ye-welding kunye nenxalenye yesiphaluka samanzi yentloko ye-fiber optical, edityaniswe kuluhlu, njengoko kuboniswe kumzobo ongezantsi:

Umpu we-welding kunye nonxibelelwano lwebhokisi yolawulo

Umpu we-welding kunye nebhokisi yokulawula isebenzisa iingcingo ezintathu ukudibanisa, kubandakanywa: umgca wamandla amabini angundoqo, i-five-core motor signal line, i-three-core yokhuseleko lokutshixa umhlaba kunye nomgca weqhosha lokuqalisa.

Iingcingo zamandla enjini/iingcingo zomqondiso (iintambo ezimbini ezimnyama) ziqhagamshelwe ngokuthe ngqo kwinxalenye yemoto yentloko yokuwelda kwaye zinokuqhawuka (ezimbini iinketho ziyafumaneka: 1. Vula isiciko semoto kunye nepleyiti esecaleni yompu wokuwelda ophathwayo 2. Vula ibhokisi yolawulo Zonke iiplagi)

Itshixa ngokukhuselekileyo kunye neqhosha lokucupha ucingo olungundoqo oluthathu olusetyenzisiweyo Iplagi yenqwelomoya esuswayo:Itshixa ngokukhuselekileyo kunye neengcingo zamaqhosha, apho i-1 iluhlaza okwesibhakabhaka, i-2 imnyama, kwaye i-3 imdaka (iqhagamshelwe kwi-pin 6/7/8 yojongano lwesiginali 1, bona ingcaciso yocingo lwebhokisi yolawulo engentla malunga neenkcukacha)

Ufakelo lwe-wire feeder

Iplagi ye-eriyali engundoqo-mbini emsileni we-feeder yocingo iqhagamshelwe kwi-pin 5/6 ye-interface yesignali 2. Bhekisela koku kulandelayo kwindlela ethile yofakelo.

Cofa: Imiyalelo yokuFakelo lweFidi yocingo(Applets)

Iphaneli yokulawula kunye nesikhokelo sokusebenza (oku kulandelayo yinguqulelo ye-V3.3)

Isishwankathelo sokusebenza kunye nesikhokelo sokusebenza

Iphaneli yokusebenza yochungechunge lwe-SUP ikakhulu yenziwe ngesikrini sokuchukumisa kunye nebhokisi yokulawula.

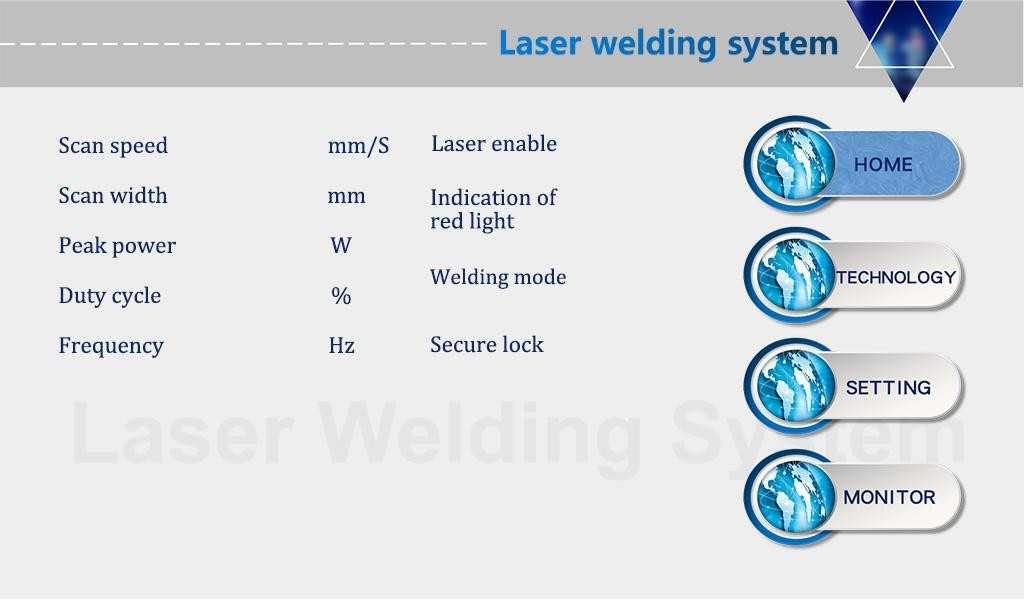

Chukumisa iphepha eliphambili, inkqubo, ukusetwa, kunye nokubeka iliso kujongano lomsebenzi.

Ukusebenza kwesikrini esiphambili kwesikrini

①Kolu jongano, unokubona iiparamitha zenkqubo yangoku kunye nolwazi lwe-alam ngoko nangoko.

②I-laser ivuliwe kwaye isalathisi esibomvu sivuliwe xa sivuliwe.

③Isitshixo sokhuseleko siqhele ukuba ngwevu, kwaye xa intloko yokuwelda ichukumisa i-workpiece, iba luhlaza kwaye inokusetyenzwa.

④ Ukukhetha imowudi yokuwelda, ukungagqibeki kuyaqhubeka.Xa isetelwe ukuba ibone i-welding, inokukhupha ukukhanya ngokuphindaphindiweyo ukwenzela ukusebenza kwe-welding, ekulungele ukulawula ixesha lokuwelda ngenxa yempazamo yomntu.Lo msebenzi ufuna ukusetwa njengoko kufuneka (uguqulelo lwe-V3.3 ngulo msebenzi ungasentla)

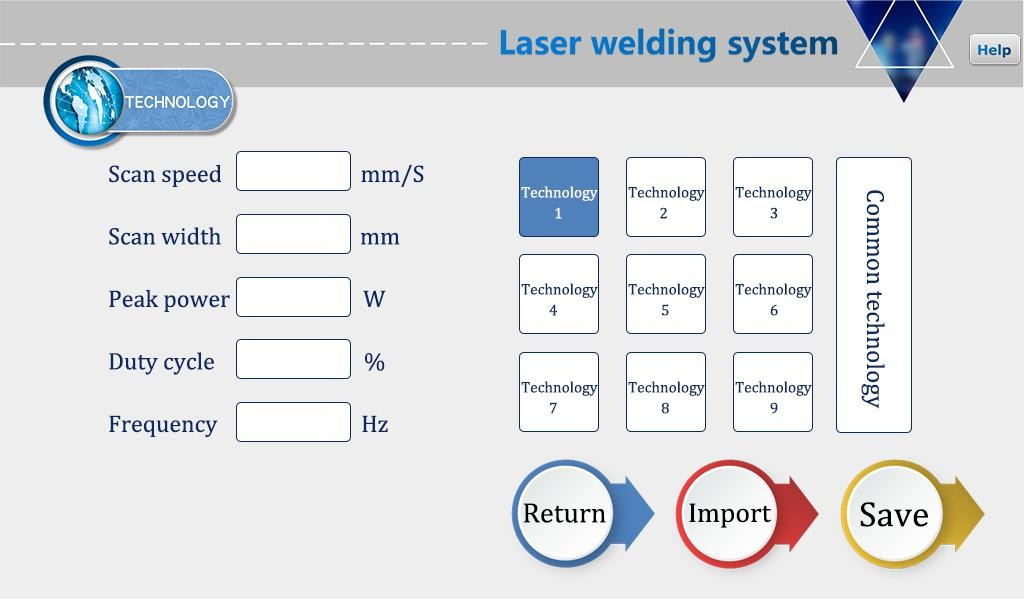

Inkqubo yokusebenza kwesikrini esikhulu

①Ujongano lwenkqubo luqulathe inkqubo yeparameters yolungiso lweempazamo, enokulungiswa ngokucofa ibhokisi.Emva kokuba uhlengahlengiso lugqityiwe, cofa u-Kulungile, uze uyigcine kwinkqubo enqumlayo.Xa uyisebenzisa, cofa ngaphandle (Guqula-Gcina-Ngenisa ngaphandle).

②Uluhlu lwesantya sokuskena yi-2-6000mm / S, kunye nobubanzi bokuskena ububanzi ngu-0^ 5mm.Isantya sokuskena sikhawulelwe bububanzi bokuskena.Ubudlelwane bokunciphisa: 10≤ isantya sokuskena / (ukuskena ububanzi * 2) ≤1000 Ukuba idlula umda, iya kuba ngokuzenzekelayo ixabiso lomda.Xa ububanzi bokuskena bumiselwe ku-0, abuyi kuskena (oko kukuthi umthombo wokukhanya) (esona santya siqhelekileyo sokuskena: 300mm/S, ububanzi 2.5mm).

③ Amandla encopho kufuneka abe ngaphantsi okanye alingane namandla elaser kwiphepha leparameter (umzekelo, amandla elaser yi 1000W, ke ixabiso alikho phezulu kune

1000).

④Uluhlu lwe-Duty ratio 0 ~ 100 (engagqibekanga i-100, ngokuqhelekileyo ayifuni ukutshintsha).

⑤Uluhlu olucetyiswayo lwe-pulse frequency yi-5-5000Hz (i-default yi-2000, ngokuqhelekileyo ayifuni ukuguqulwa).

NONE

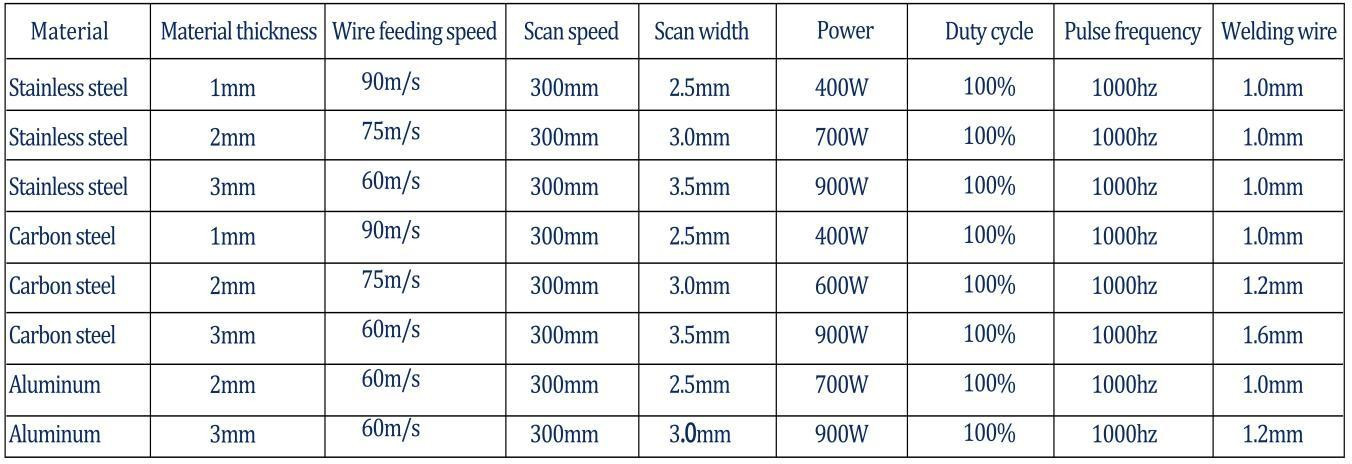

Isalathiso senkqubo (ngokuxhomekeke kwimiqathango eyiyo, oku kulandelayo kubhekiselele kuphela)

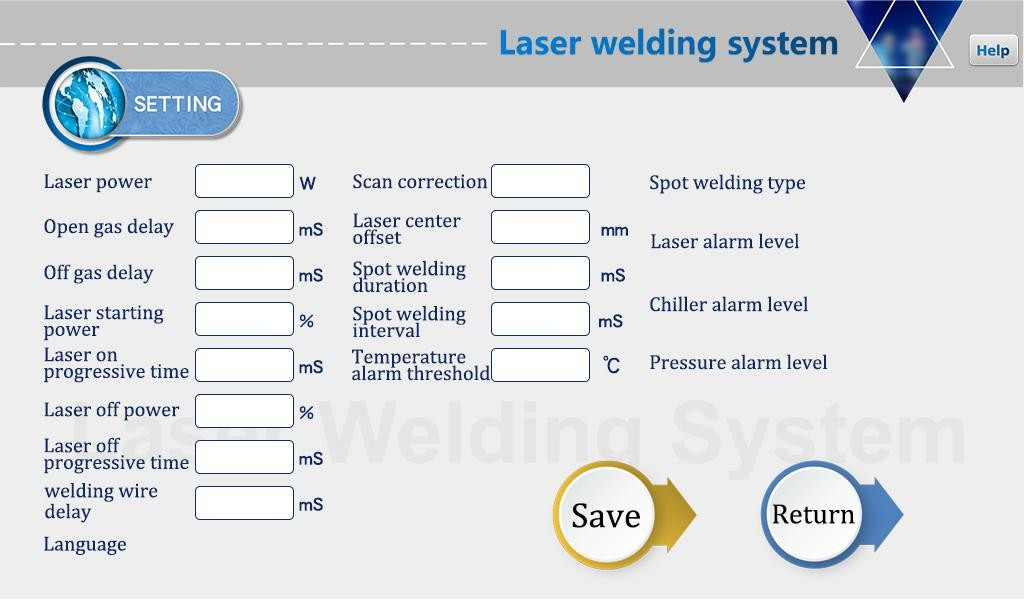

Cwangcisa isikrini esiphambili

Igama lokugqitha 123456

① Amandla e-laser ngamandla amakhulu e-laser asetyenzisiweyo.

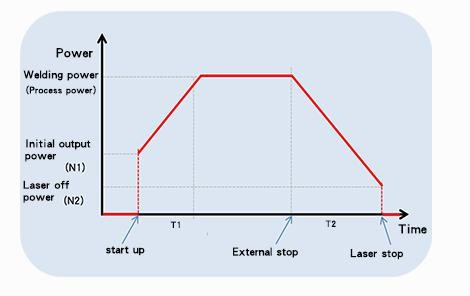

②Ukutshintsha ukulibaziseka komoya kutshintsha kwi-200ms, kwaye uluhlu luyi-200ms-3000ms.

③Xa ukukhanya kulayitiwe, kuya kwanda kancinci ukusuka kwi-N1% yamandla enkqubo ukuya kwi-100%;xa ukukhanya kucinyiwe, kuya kwanda ngokuthe ngcembe ukusuka kwi-100% yamandla enkqubo.

ukuya ku-N2;(njengoko kubonisiwe kulo mfanekiso ungezantsi).

④Imbuyekezo yokulibaziseka kokutya kocingo lixesha lokutya kwangaphambili xa kuthelekiswa nomqondiso wokukhanya, onokusetyenziswa kunye nomsebenzi wokurhoxisa.

⑤Iqondo eliphezulu le-alarm threshold yi-70℃.Xa ixabiso libekwe kwi-0, i-alamu yeqondo lokushisa ayiyi kufunyanwa.

⑥Skena uluhlu lwe-coefficient yolungiso 0.01~4, i-coefficient yobubanzi bomgca wethagethi/ububanzi bomgca wokulinganisa: ngokubanzi 1.25.

⑦ I-Laser center offset -3 ~ 3mm, yinciphise kwaye uyihambise ngakwesobunxele, yandise kwaye uyihambise ekunene.

⑧ Isiginali yenqanaba le-alarm yinto engagqibekanga, kwaye i-alamu ekhuselweyo ingatshintshwa ngokuthe ngqo kwinqanaba elihambelanayo lokuchongwa.

⑨Ubude bexesha le-spot welding lixesha lokukhutshwa kokukhanya emva kokutsala i-trigger, oko kukuthi, nokuba iqhosha likhululiwe, ukukhanya kuya kukhutshwa ngokwexesha elichithwe (i-V3.3 version ngumsebenzi ongentla)

⑩Ixesha lekhefu lendawo yokuwelda lixesha lokukhanya lokumisa phakathi kweendawo ezimbini zokuwelda emva kokutsala iqhosha lokutsala (uguqulelo lweV3.3 kunye nomsebenzi ongentla)

⑧ Cofa iqhosha le-HELP phezulu ekunene ukuze ufumane ingcaciso yeparameter eyongezelelekileyo.

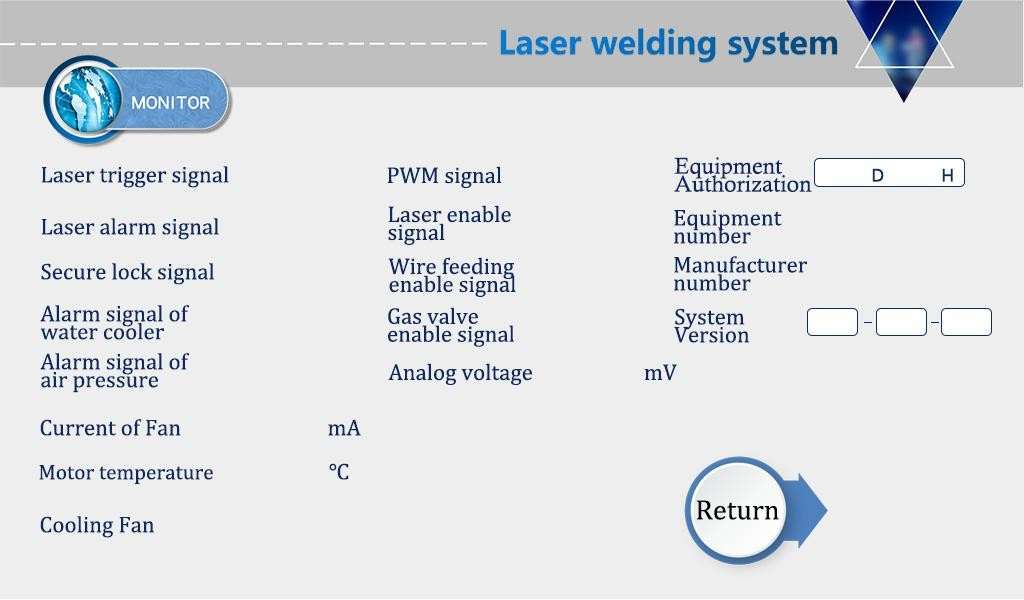

Ujongano olungundoqo ujongano

Olu jongano lubonisa ubume bophawu ngalunye lophawu kunye nolwazi lwesixhobo

Cofa kugunyaziso lwesixhobo ukufaka ujongano lwexesha lokusebenzisa olugunyazisiweyo, emva kokungena igama eligqithisiweyo, inkqubo inokugunyaziswa ukusetyenziswa kwexesha.

Indlela yoguqulelo oluntsonkothileyo kunye neendlela zokuyifihla ziyafana:

Indlela yokususa uguqulelo lwenkqubo (i-Apple)amandla amakhulu, kusetyenziso ngokubanzi ukuya kuthi ga kwi-3000w;

ubungakanani obuncinci, ubunzima obulula, imvakalelo engcono yesandla;

i-disassembly elula ngakumbi;

kunzima ukunxiba