umpu welding we-laer obambe ngesandla

umpu wokuwelda obambe ngesandla,

Intloko ye-laser ye-welding ephathwayo, i-laser welding head factory ephathwayo, umenzi wentloko we-laser welding, i-wholesale laser welding head,

Ukhuseleko – Ukhuseleko

Inkqubo yokufumanisa ukhuseleko oluphuhliswe ngokwakho kunye nee-alamu ezininzi zokhuseleko ezisetiweyo, zikhuselekile kwaye zizinzile

Ukugcina ixesha - ngokufanelekileyo kwaye kulula

Isibuko sokugxila kunye nedrowa yesibuko sokukhusela, kulula ukuyibuyisela

I-lightweight -- ilula kunye nomthwalo omncinci

Ubungakanani obuncinci, ubunzima obulula, ukusebenza okuguquguqukayo, kulula ukuyisebenzisa

Umgangatho - umsebenzi ozinzileyo we-welding

Amandla aphezulu e-welding, i-deformation encinci, ubunzulu bokunyibilika okuphezulu

Ukusebenza - imisebenzi emininzi

Inkxaso ephathwayo eqhubekayo yokuwelda, ukuwelda indawo, ukucoca, ukusika, "isandla" "ukusuka" - umzimba, ugunyaziso lokugqitha

Sizibophelele kulawulo olungqongqo lomgangatho kunye nenkonzo yabathengi enenkathalo, kwaye abasebenzi bethu abanamava baya kuxoxa ngeemfuno zakho nawe nangaliphi na ixesha.Umthamo wemveliso wonyaka wenkampani udlula iiyunithi ezingama-20,000, kwaye umthamo wonyaka wemveliso unokufikelela ngaphezu kweeyunithi ezingama-30,000.Iimveliso zethu zithengisa kakuhle kuzo zonke izixeko namaphondo kulo lonke elaseTshayina, kwaye zithunyelwa kumazwe angaphandle kubathengi abakwiManyano yaseYurophu nakwamanye amazwe nakwimimandla.

Kwangaxeshanye, siyakwamkela iOEM kunye neodolo yeODM.Ndiyathemba ukuba singaba ngamaqabane asondeleyo kunye nexesha elide!

1) Qinisekisa ukusekwa okuthembekileyo phambi kokunikezelwa kombane.

2) Intloko ye-laser output idibaniswe nentloko ye-solder.Nceda ujonge intloko yemveliso ye-laser ngononophelo ukuthintela uthuli okanye olunye ungcoliseko xa usebenzisa.Xa ucoca intloko ye-laser output, nceda usebenzise iphepha elikhethekileyo lens.

3) Ukuba isixhobo asisetyenziswanga ngokuhambelana nendlela echazwe kule ncwadana, ingonakaliswa ngokushiya isixhobo kwimeko yokusebenza engaqhelekanga.

I-4) Xa utshintsha i-lens yokukhusela, nceda unakekele ukhuseleko.

I-5) Nceda uqaphele: Xa usebenzisa isixhobo okokuqala, xa ukukhanya okubomvu kungenakukhutshwa kwi-port yethusi, nceda uqaphele ukuba ungakhanyi.

Iinkcukacha zokuziswa kwephakheji ye-welding ebambe ngesandla

★Umaleko wokuqala

SUP20S intloko welding 1pc

Inkqubo 1 iseti

Inkqubo yentambo yomgangatho we-10m

★Umaleko wesibini

Umbhobho wobhedu 7pcs Ukusika umbhobho 1pc

Isikali ityhubhu 1pc

Isibuko sokhuseleko 10pcs

Ikliphu ye-Grounding 1pc

Intambo yoqhagamshelo lwesikrini 1m

Bonisa ihitch 1 iseti

★Umaleko wesithathu

Bonisa isikrini 1pcs

Ukutshintsha amandla 2pcs

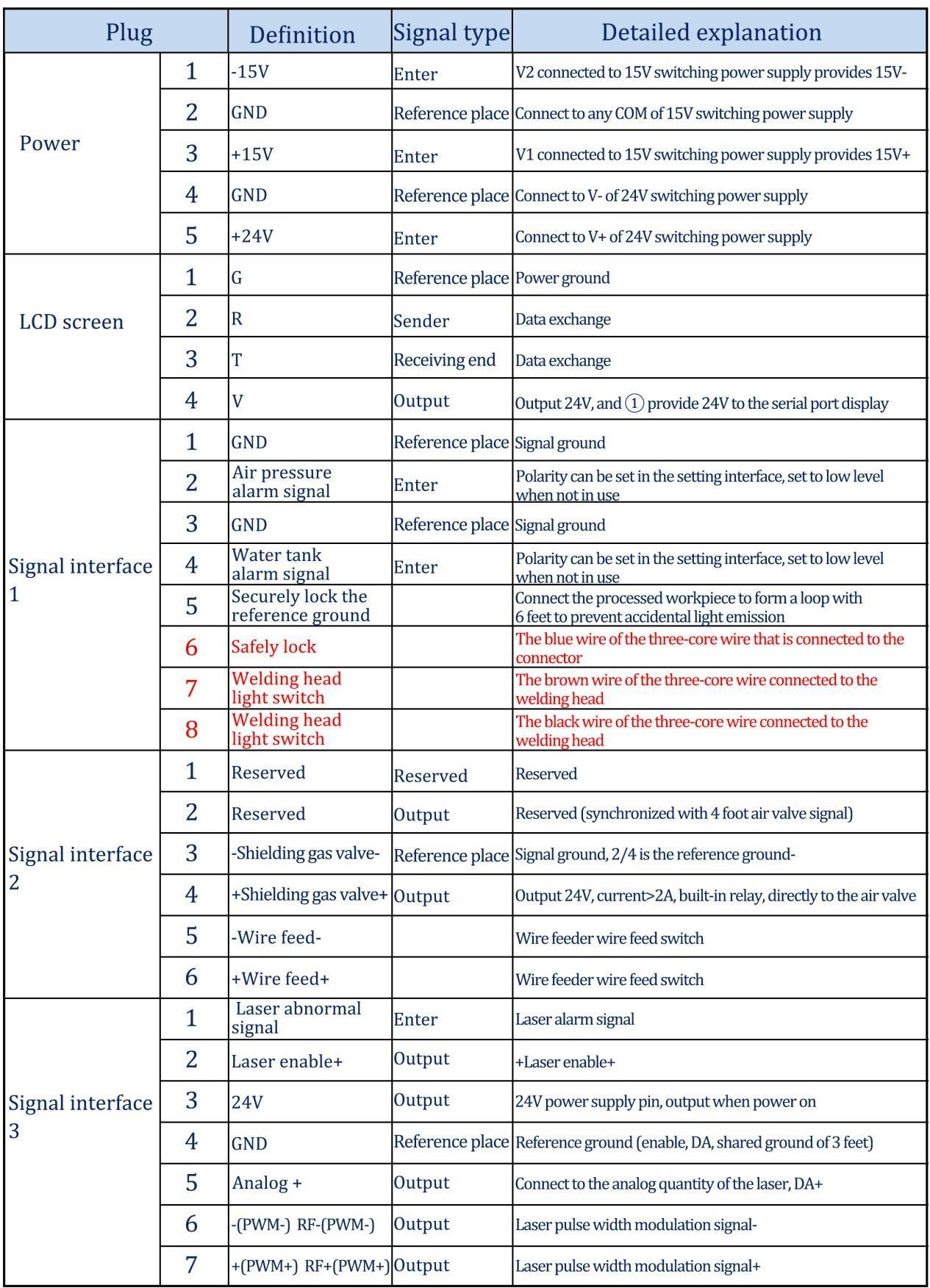

Inkcazo yocingo yomlawuli

Umlawuli wetheminali yonikezelo lwamandla

Umbane usebenzisa i-5P ikhonkco kwaye inikwe amandla usebenzisa i-24V yokutshintsha umbane kunye ne-15V yokutshintsha umbane onikeziweyo.

Nceda uqaphele ukuba umbane we-15V wokutshintsha umbane ukwahlula phakathi kokulungileyo kunye nokubi, i-V1 ixhunyiwe kwi-15V +, i-V2 ixhunyiwe kwi-15V-, kwaye nayiphi na i-COM kwi-15V yokutshintsha umbane ixhunyiwe kwi-pin 2 GND!

Nceda uqaphele ukuba umbane wokutshintsha kufuneka usekelwe!

Umlawuli LCD24/5000

Intambo yeLCD ihanjiswa kunye nesixhobo kwaye inokudityaniswa ngokuthe ngqo.Jonga umfanekiso ongentla ngenkcazelo ethile

Ujongano lophawu lomlawuli 1

①/②Iphini luphawu loxinzelelo lomoya lokungenisa, ukuba ufuna ukwenza (ucingo olufunekayo), nceda usete inqanaba le-alam yoxinzelelo lomoya ngasemva phezulu, kungenjalo iphantsi.

I-Pin ③/④ luphawu lwe-alam yetanki yamanzi.Ukuba ufuna ukuyenza (i-wiring efunekayo), setha inqanaba le-alamu yoxinzelelo lomoya ukuya phezulu ngasemva, kungenjalo iphantsi.

I-pin yenombolo ngumhlaba wesalathiso wokutshixa umhlaba wokhuseleko kwaye ifakwe ngqo kwi-workpiece yenkqubo.

I-pin yenombolo yindawo yokhuseleko lomhlaba wentloko ye-weld, eqhagamshelwe kwintambo eluhlaza okwesibhakabhaka yocingo oluthathu, xa intloko ye-weld ichukumisa i-workpiece, i-lock yokhuseleko ivuliwe ngeli xesha.

I-Pin No. yi-weld head's on/off switch, eqhagamshelwe kucingo olumdaka lwentambo engundoqo zintathu.

I-Pin No. yi-switch yokukhanya yentloko ye-weld, edityaniswe kucingo olumnyama lwe-three-core wire, xa i-trigger itsalwa, iqhosha le-trigger likhanya.

Nceda uqaphele ukuba umqondiso wemveliso wamazibuko alandelayo uya kuthunyelwa kuphela ukuba akukho alamu kunye nomqondiso wokutshixa ukhuseleko kunye neqhosha lokuqalisa livuliwe.

Ujongano lwesiginali yomlawuli 2

I-interface ye-signal interface ye-2 ekupheleni isebenzisa i-interface ye-6P, kunye nomgca ongenayo ohambelana ne-valve yomoya

① Unyawo olugciniweyo

② iphini eligciniweyo (elingqanyaniswe ne-4-pin signal)

③/④ iphini yi-24V ephumayo yevalvu yomoya, eqhagamshelwe kwivalvu yomoya

⑤/⑥ unyawo luphawu lomgca we-wire feeder, eyi-port ye-signal ye-wire feeder, kwaye ayahlulwe ibe yinto efanelekileyo kunye nengalunganga.

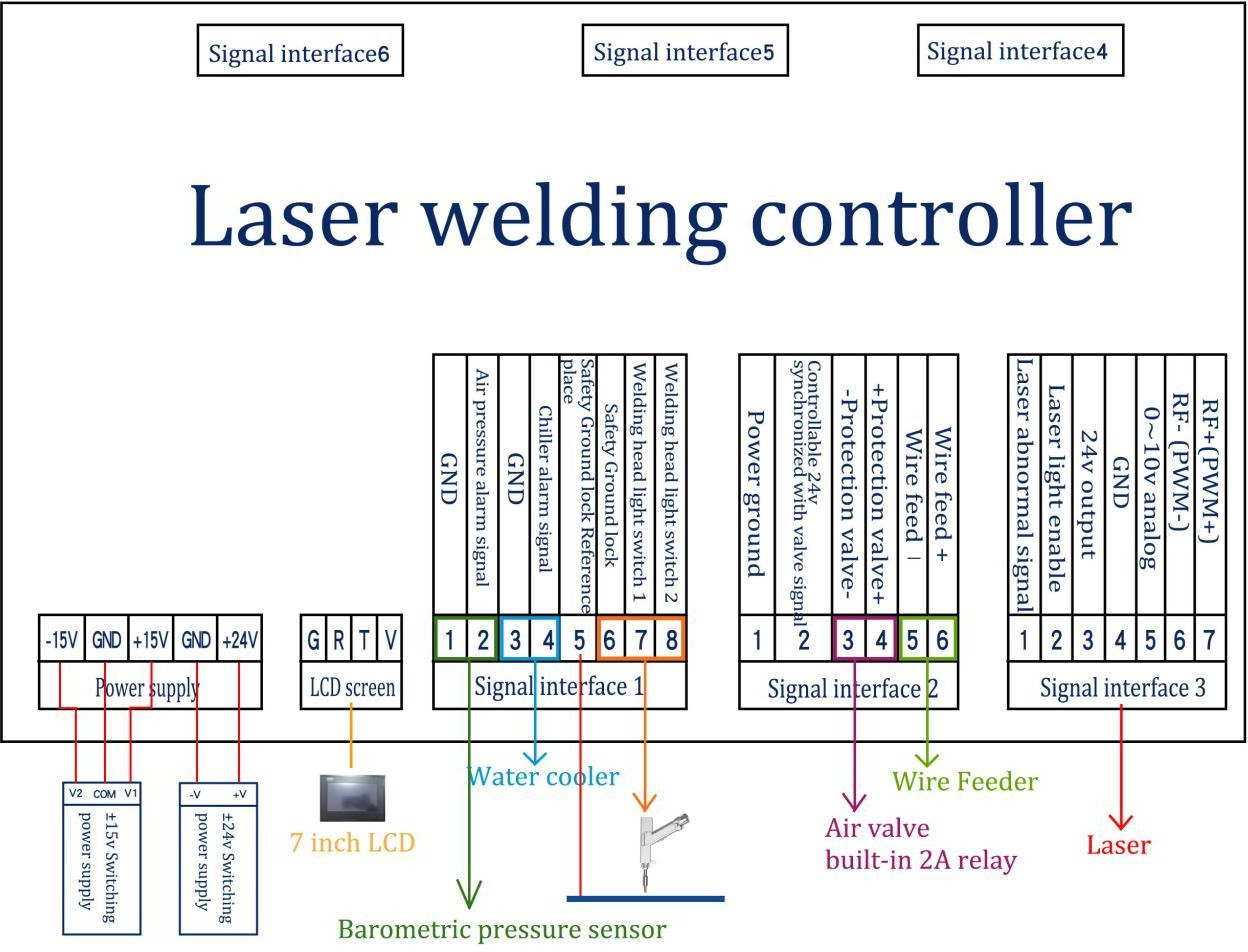

Umzobo wocingo lomlawuli

①/②Iphini luphawu loxinzelelo lomoya lokungenisa, ukuba ufuna ukwenza (ucingo olufunekayo), nceda usete inqanaba le-alam yoxinzelelo lomoya ngasemva phezulu, kungenjalo iphantsi.

I-Pin ③/④ luphawu lwe-alam yetanki yamanzi.Ukuba ufuna ukuyenza (i-wiring efunekayo), setha inqanaba le-alamu yoxinzelelo lomoya ukuya phezulu ngasemva, kungenjalo iphantsi.

I-pin yenombolo ngumhlaba wesalathiso wokutshixa umhlaba wokhuseleko kwaye ifakwe ngqo kwi-workpiece yenkqubo.

I-pin yenombolo yindawo yokhuseleko lomhlaba wentloko ye-weld, eqhagamshelwe kwintambo eluhlaza okwesibhakabhaka yocingo oluthathu, xa intloko ye-weld ichukumisa i-workpiece, i-lock yokhuseleko ivuliwe ngeli xesha.

I-Pin No. yi-weld head's on/off switch, eqhagamshelwe kucingo olumdaka lwentambo engundoqo zintathu.

I-Pin No. yi-switch yokukhanya yentloko ye-weld, edityaniswe kucingo olumnyama lwe-three-core wire, xa i-trigger itsalwa, iqhosha le-trigger likhanya.

Nceda uqaphele ukuba umqondiso wemveliso wamazibuko alandelayo uya kuthunyelwa kuphela ukuba akukho alamu kunye nomqondiso wokutshixa ukhuseleko kunye neqhosha lokuqalisa livuliwe.

Ujongano lwesiginali yomlawuli 2

I-interface ye-signal interface ye-2 ekupheleni isebenzisa i-interface ye-6P, kunye nomgca ongenayo ohambelana ne-valve yomoya

① Unyawo olugciniweyo

② iphini eligciniweyo (elingqanyaniswe ne-4-pin signal)

③/④ iphini yi-24V ephumayo yevalvu yomoya, eqhagamshelwe kwivalvu yomoya

⑤/⑥ unyawo luphawu lomgca we-wire feeder, eyi-port ye-signal ye-wire feeder, kwaye ayahlulwe ibe yinto efanelekileyo kunye nengalunganga.

Ujongano lwesignali yomlawuli 3

I-Pin luphawu lwe-alaser igalelo +, ukuba ufuna ukwenza, nceda usete inqanaba le-alam yoxinzelelo lomoya ukuya kwinqanaba eliphezulu ngasemva.

I-pin iyasebenza+, qhagamshela i-laser enable+.

I-Pin No. 3 yimveliso ye-24V, imveliso ye-24V + ngqo emva kombane

I-Pin Nomb. ④ ngumhlaba oqhelekileyo (umhlaba wesalathiso wephini 1/2/3/5)

Inombolo yePin yi-analog + imveliso, i-analog inikwe

Inombolo ye-Pin yi-PWM yesiginali yokumodareyitha

Iphini yedijithali yiPWM+ isignali emodareyithayo ⑦ Iphini yedijithali yiPWM+ isignali emodareyithayo.

Umzobo wocingo lomlawuli

Qaphela: I-terminal ye-COM ye-±15V yokutshintsha umbane kunye ne--V (0V) i-terminal ye-+24V yokutshintsha umbane kufuneka iqhagamshelwe kwi-GND kwaye iqhagamshelwe ngokupheleleyo kwi-workpiece ngexesha elinye.Imeko yokunikezelwa kwamandla okutshintsha kufuneka idibaniswe phantsi, ngaphandle koko i-alarm yomhlaba yokuvala ukhuseleko ingenzeka kwaye ayiyi kukhanyisa.

Ujongano lwegalelo lokubona

Iintloko zokuwelda ze-SUP ziyafumaneka kuninzi lweejenereyitha ze-laser zamashishini.I-fiber optic interfaces eziqhelekileyo ezisetyenziswayo ziyi-IPG, i-RICO, i-Troncin, i-FIBO, i-Tottenham, i-Jephte, i-Caplin, njl njl. I-optics kufuneka igcinwe icocekile kwaye icocwe kulo lonke uthuli ngaphambi kokusetyenziswa

Xa ufaka i-fiber, intloko yokusika kufuneka ijikelezwe i-90 degrees ukwenzela ukuba i-horizontal ngaphambi kokusebenzisa i-fiber ukukhusela uthuli ekuweleni kwi-interface.

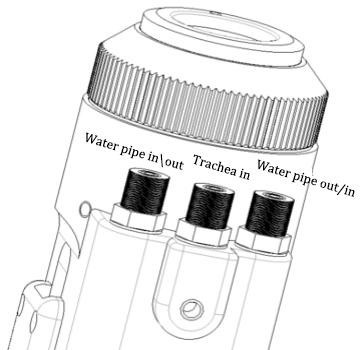

Ukhuselo lwegesi kunye ne-water chiller interface

Ujongano lombhobho wamanzi kunye negesi lunokufakwa kunye ne-6MM yangaphandle ye-diameter kunye ne-4MM yangaphakathi ye-hose ye-diameter.Umgca wegesi ungena phakathi, kwaye ukungena kwamanzi kunye nemibhobho yokuphuma kumacala omabini (ngaphandle kokuqwalasela ulwalathiso lokungena kwamanzi kunye nokuphuma), njengoko kuboniswe ngezantsi.

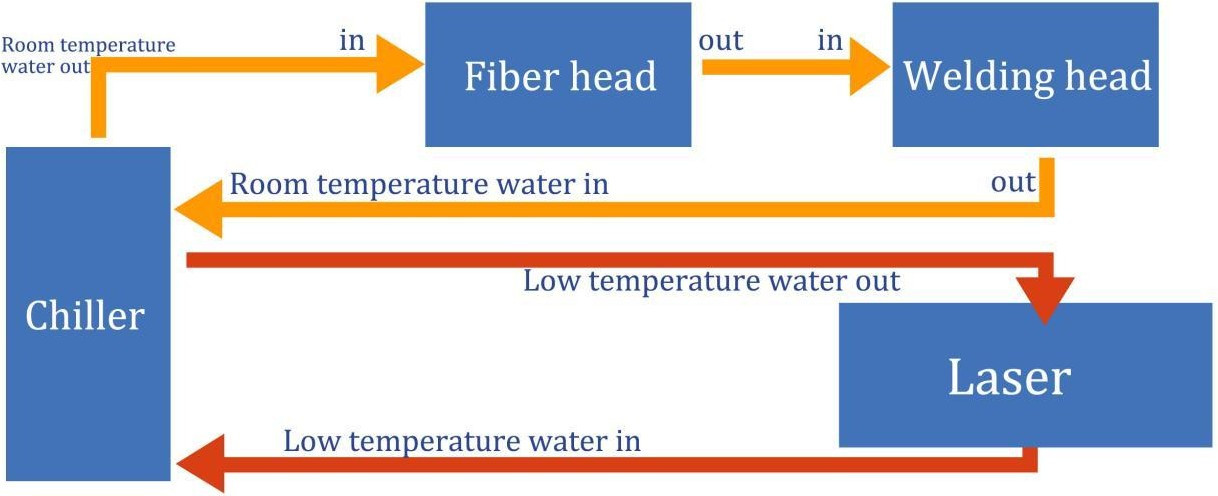

Inkqubo yokupholisa yahlulwe kwisiphaluka samanzi inxalenye yentloko ye-welding kunye nenxalenye yesiphaluka samanzi yentloko ye-fiber optical, edityaniswe kuluhlu, njengoko kuboniswe kumzobo ongezantsi:

Umpu welding kunye nebhokisi yokulawula unxibelelwano lonxibelelwano

Unxibelelwano lonxibelelwano lwe-welding gun kunye nebhokisi yokulawula

Umpu we-welding uqhagamshelwe kwibhokisi yokulawula kunye neentambo ezintathu, ezibandakanya: i-core motor power wire, i-five-core motor signal wire, i-three-core yokhuseleko lokutshixa umhlaba kunye ne-trigger wire.

I-motor power / iingcingo zesignali (iingcingo ezimbini ezimnyama) ziqhagamshelwe ngokuthe ngqo kwinxalenye yemoto yentloko ye-welding kwaye inokususwa (iinketho ezimbini: 1. Vula isiciko semoto kunye necala lecala letotshi ephathwayo 2. Vula ibhokisi yokulawula zombini ziplagiwe)

Isitshixo sokhuseleko kunye neqhosha lokucupha ucingo oluthathu olungundoqo olusetyenzisiweyo Iplagi yenqwelomoya esuswayo: isitshixo sokhuseleko kunye nocingo lweqhosha, apho i-1 iluhlaza okwesibhakabhaka, i-2 imnyama, i-3 imdaka (iqhagamshelwe kujongano lomqondiso 1 pin 6/7/8, bona ingcaciso yocingo lwebhokisi yolawulo engentla).

Ufakelo lwe-wire feeder

Iplagi ye-aviation ye-core-core ekupheleni kwe-wire feeder ixhunyiwe kwi-pin 5/6 ye-interface ye-signal 2. Nceda ubhekisele koku kulandelayo kwindlela yofakelo oluthile.

Cofa.Imiyalelo yokufakela isixhasi ngocingo (Applets).

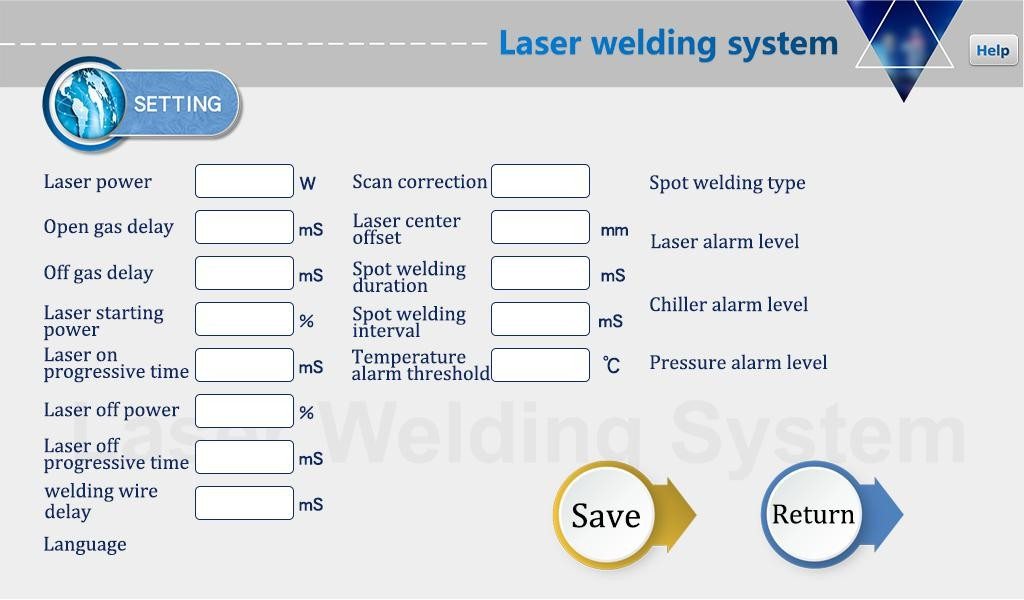

Iphaneli yokulawula kunye nesikhokelo sokusebenza (uguqulelo lwe-V3.3 ngezantsi).

Isishwankathelo sokusebenza kunye nesikhokelo sokusebenza

Iphaneli yokusebenza yochungechunge lwe-SUP ikakhulu iqulathe isikrini sokuchukumisa kunye nebhokisi yokulawula.

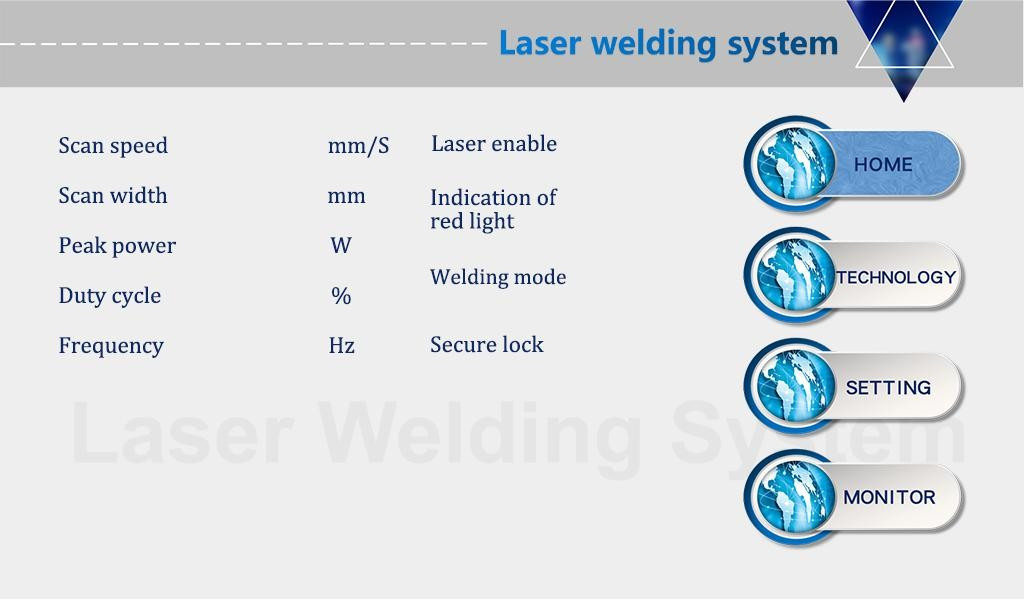

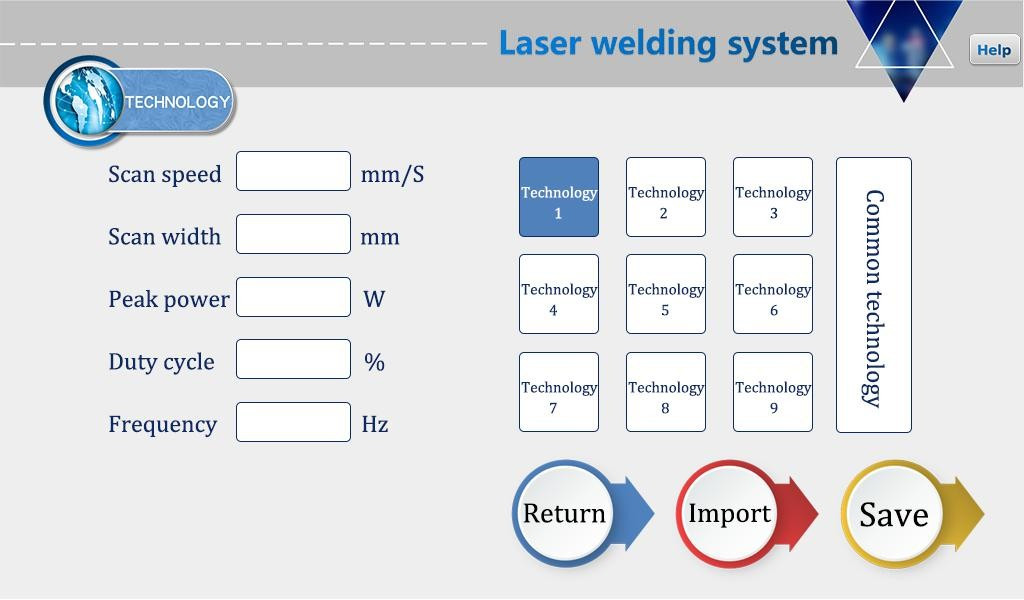

Chukumisa iphepha eliphambili, inkqubo, ukuseta, ukubeka iliso kunye nezinye izikrini zokusebenza.

Ukusebenza kwesikrini esiphambili kwesikrini

①Kwesi sikrini, unokubona iiparamitha zenkqubo yangoku kunye nolwazi lwe-alam ngoko nangoko.

②I-laser inikwe amandla kwaye ukukhanya kwesalathisi kubomvu xa ivuliwe.

③Isitshixo sokhuseleko siqhele ukuba ngwevu kwaye sijike sibe luhlaza xa intloko ye-weld ichukumisa umsebenzi kwaye inkqubo inokuqhutywa.

④Imo yewelding ikhethiwe, kwaye ukungagqibeki kuyaqhubeka.Xa imiselwe ukuba ibone ukuwelda, inokukhanya ngokunqamkileyo ukuze isebenze i-welding, ekulula ukuyilawula ixesha lokuwelda ngenxa yempazamo yomntu.Lo msebenzi ufuna ukusetwa njengoko kufuneka (uguqulelo lwe-V3.3 kulo msebenzi ungentla)

Inkqubo yokusebenza kwesikrini esikhulu

①Inkqubo yesikrini iqulathe inkqubo yeparameters yolungiso lweempazamo, enokulungiswa ngokucofa ibhokisi.Emva kokuba ugqibile ukulungisa, cofa u-Kulungile uze uyigcine kwiNkqubo eKhawulezayo.Ukusebenzisa, cofa u-Ngenisa (Guqula-Gcina-Ngenisa ngaphandle).

②Uluhlu lwesantya sokuskena yi-2-6000mm/S kunye nobubanzi bokuskena ububanzi ngu-0^5mm.Isantya sokuskena sikhawulelwe bububanzi bokuskena.Ubudlelwane bomda yi.10≤ isantya sokuskena/(scan wide*2)≤1000 Ukuba umda ugqithisiwe, uya kuba lixabiso lomda ngokuzenzekelayo.Xa ububanzi bokuskena bumiselwe ku-0, akuyi kubakho ukuskena (oko kukuthi umthombo wenqaku) (esona santya siqhelekileyo sokuskena: 300mm/S, ububanzi 2.5mm).

Amandla aphezulu kufuneka abe ngaphantsi okanye alingane namandla e-laser kwiphepha leparameter (umzekelo, ukuba amandla e-laser yi-1000W, ixabiso alikho ngaphezu

1000).

④Uluhlu lwereyithi yomthwalo yi-0 ~ 100 (eyokuqala yi-100, ngokuqhelekileyo akukho mfuneko yokutshintsha).

Uluhlu olukhuthazwayo lwe-pulse frequency yi-5-5000Hz (i-default yi-2000, ngokuqhelekileyo akukho mfuneko yokutshintsha).

Cofa iqhosha elithi "Nceda" phezulu ekunene ukuze ufumane ingcaciso yeeparamitha ezifanelekileyo.

Isalathiso senkqubo (ngokuxhomekeke kwimiqathango eyiyo, oku kulandelayo kubhekiselele kuphela)

Seta isikrini esiphambili sokusebenza

Igama lokugqitha 123456

Amandla e-laser awona mandla aphezulu e-laser asetyenziswayo.

②Ukulibaziseka komoya wokutshintsha yi-200ms ngokungagqibekanga, kwaye uluhlu luyi-200ms-3000ms.

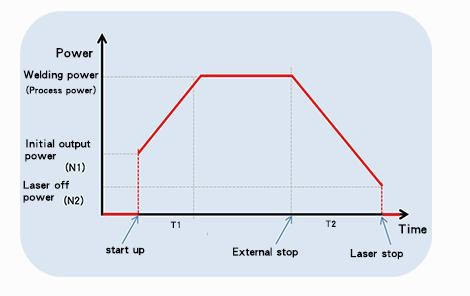

③Isibane sikhanyisa ngokuthe ngcembe ukusuka kwi-N1% ukuya kwi-100% yamandla enkqubo;xa ukukhanya kucinyiwe, ngokuthe ngcembe kwandisa ukusuka kwi-100% yamandla enkqubo.

ukuya ku-N2;(njengoko kubonisiwe kulo mfanekiso ungezantsi).

④Imbuyekezo yokulibaziseka kwefidi yomgca inxulumene nexesha elingaphambi kwexesha lokutya komgca we-optical signal kwaye ingasetyenziswa kunye nomsebenzi wokuhlenga.

⑤ Iqondo eliphezulu lobushushu be-alarm yi-70 ° C.Xa ixabiso libekwe kwi-0, i-alamu yeqondo lokushisa ayiyi kufunyanwa.

⑥Uluhlu lwe-coefficient yokulungiswa kokuskena 0.01~4, i-coefficient yobubanzi bomgca wokulinganisa/ububanzi bomgca wokulinganisa: ngokubanzi 1.25.

⑦ I-laser center offset yi-3 ~ 3mm, iyancipha ukuya ekhohlo kwaye inyuke ukuya ngasekunene.

⑧ isignali yenqanaba le-alam yinto engagqibekanga, i-alamu yekhaka inokutshintshwa ngokuthe ngqo kwinqanaba elihambelanayo lokuchongwa.

⑨ Ubude bexesha le-welding libhekisela kwixesha lokukhutshwa kokukhanya emva kokutsala i-trigger, oko kukuthi, nokuba iqhosha likhululiwe, liya kukhanya ngokwexesha elichithwe (uguqulelo lwe-V3.3 lomsebenzi ongentla)

Ixesha lesithuba sesithuba sokuwelda lixesha lokukhanya lokumisa phakathi kweendawo ezimbini zokuwelda emva kokutsala iqhosha lokutsala (V3.3 uguqulelo lomsebenzi ongasentla)

⑧ Cofa iqhosha le-HELP phezulu ekunene ukuze ufumane inkcazelo engakumbi yeeparamitha ezifanelekileyo.

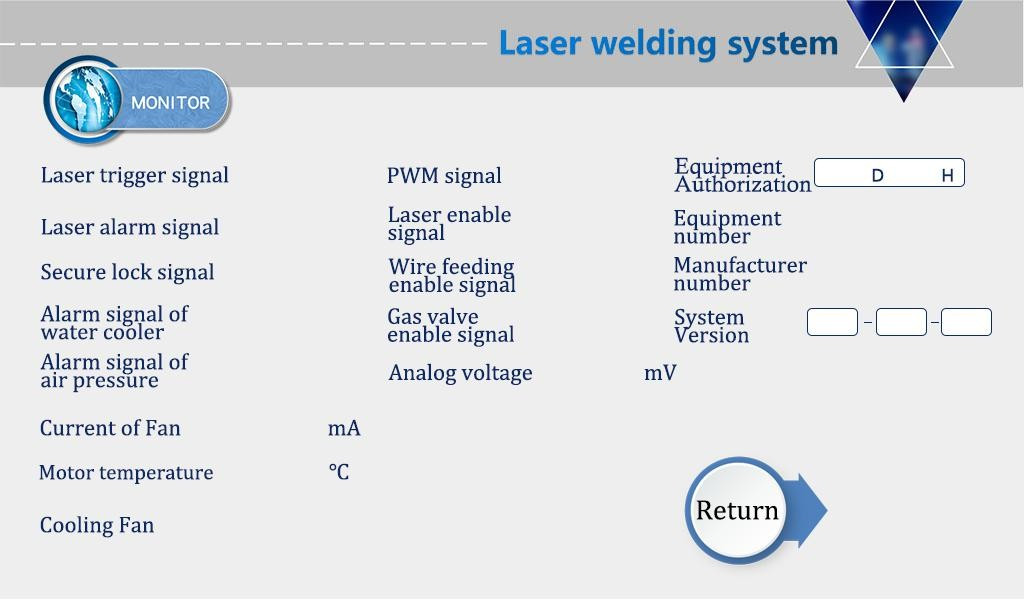

Ujongano lojongano oluphambili

Olu jongano lubonisa ubume bophawu ngalunye lophawu kunye nolwazi lwesixhobo

Cofa kwisigunyaziso sesixhobo ukufaka ujongano lwexesha lokusebenzisa olugunyazisiweyo, emva kokufaka igama eligqithisiweyo, inkqubo inokugunyaziswa ixesha lokusetyenziswa.

Indlela yokucima isixokelelwano

Olu hlobo lwentloko ye-laser welding yenye yeemveliso zethu zokuthengisa ezishushu, zixhasa iilwimi ezisibhozo.