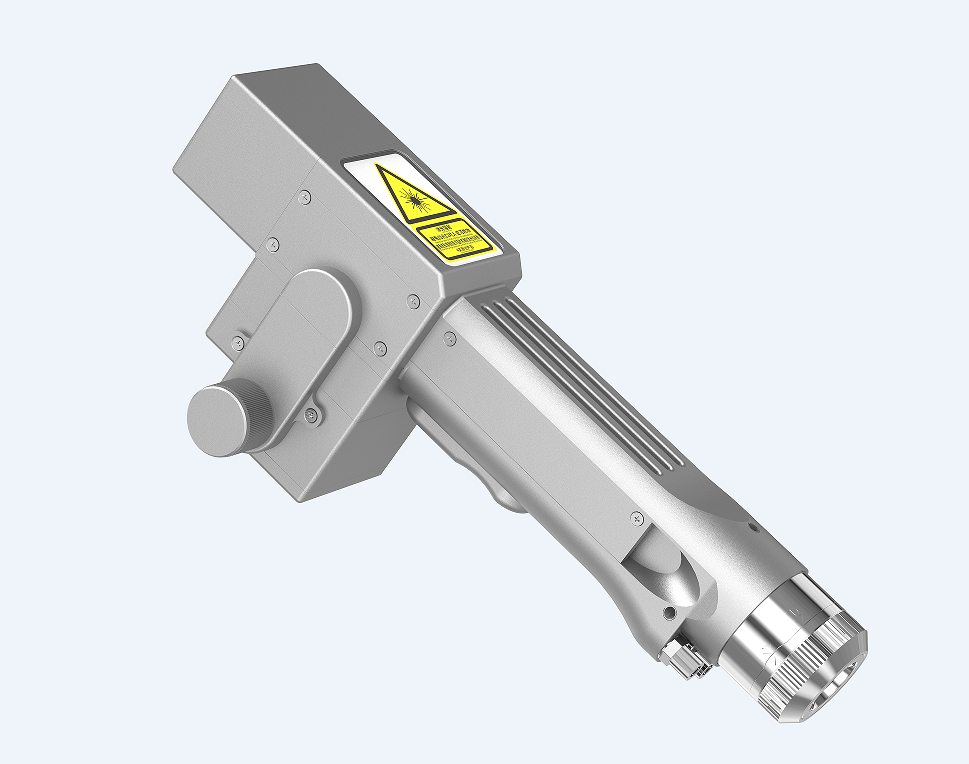

Intloko yokuCoca iLaser ebambe ngesandla SUP 22C

Intloko ye-welding ephezulu i-handheld welding cut head eqaliswe ngo-2019. Imveliso igubungela izibhamu ze-welding ezibanjwe ngesandla kunye neenkqubo zokulawula eziziphuhlisileyo, kwaye zixhotyiswe ngama-alamu amaninzi okhuseleko kunye namandla asebenzayo akhuselekileyo kunye nezicwangciso zokukhanya.Le mveliso inokutshintshwa kwiintlobo ezahlukeneyo ze-fiber lasers;i-optical optical kunye noyilo olupholileyo lwamanzi luvumela intloko ye-laser ukuba isebenze ngokuzinzileyo ixesha elide phantsi kwe-2000W.

Iimpawu eziphambili: Inkqubo yokulawula ukuziphuhlisa, ii-alamu ezininzi zokhuseleko, ubungakanani obuncinci, ukusebenza okuguquguqukayo kunye nokulula ukuyisebenzisa.

Izinzile ngakumbi: Zonke iiparameters ziyabonakala, ukujonga ixesha langempela kwimeko yomatshini wonke, ukuphepha iingxaki kwangaphambili, kulula ngakumbi ukulungisa iingxaki kunye nokusombulula iingxaki, ukuqinisekisa ukusebenza okuzinzile kwentloko ye-welding.

Inkqubo: Zonke iiparamitha ziyabonakala, umgangatho wokucoca uphelele ngakumbi.

Iiparamitha ezizinzileyo kunye nokuphindaphinda okuphezulu: uxinzelelo lomoya we-nozzle kunye ne-lens state, nje ukuba amandla e-laser azinzile, iiparitha zenkqubo kufuneka ziphindwe.Ukuphucula kakhulu ukusebenza kakuhle, ngelixa kuncitshiswa neemfuno zabaqhubi.

| Ukubonelela ngeVoltge(V) | 220±10%V AC50/60Hz |

| Indawo yokubeka | Igudile, ayinakungcangcazela kunye nefuthe |

| Ubushushu beNdawo yokuSebenza | 10-40 |

| Ukufuma kweNdawo yokuSebenza | <70 |

| Indlela yokupholisa | Amanzi-Ukupholisa |

| Ubude beWaveleng obusebenzayo | 1070nm(±10nm) |

| Amandla asebenzayo | ≤3000W |

| Ukudityaniswa | D20*3.5 F50 |

| Gxininisa | D20 F400 iilensi zeconcave cylindrical |

| D20 F800 iilensi zeconcave cylindrical | |

| Ukucamngca | 20*15.2 T1.6 |

| Iinkcukacha zeeglasi eziKhuselayo | D30*5 |

| Ubuninzi boxinzelelo lweNkxaso | 15bar |

| Uluhlu loLungiso lweNdawo | Umgca0-300mm |

| Ubunzima | 1.0KG |

1) Qinisekisa ukusekwa okuthembekileyo phambi kokunikezelwa kombane.

2) Intloko yokuphuma kwe-laser idibene nentloko ye-welding.Nceda ujonge intloko yemveliso ye-laser ngononophelo xa usebenzisa ukuthintela uthuli okanye olunye ungcoliseko.Xa ucoca intloko ye-laser output, nceda usebenzise iphepha elikhethekileyo lens.

3) Ukuba isixhobo asisetyenziswanga ngokuhambelana neendlela ezichazwe kule ncwadana, sinokuthi sisebenze ngokungaqhelekanga kwaye sibangele umonakalo.

I-4) Xa utshintsha i-lens yokukhusela, nceda uqinisekise ukuba uyayikhusela.

5) Nceda uqaphele: Xa usebenzisa okokuqala, Musa ukukhupha ukukhanya xa ukukhanya okubomvu kungabonakali.