Umbhobho weCopper we-Welding Head

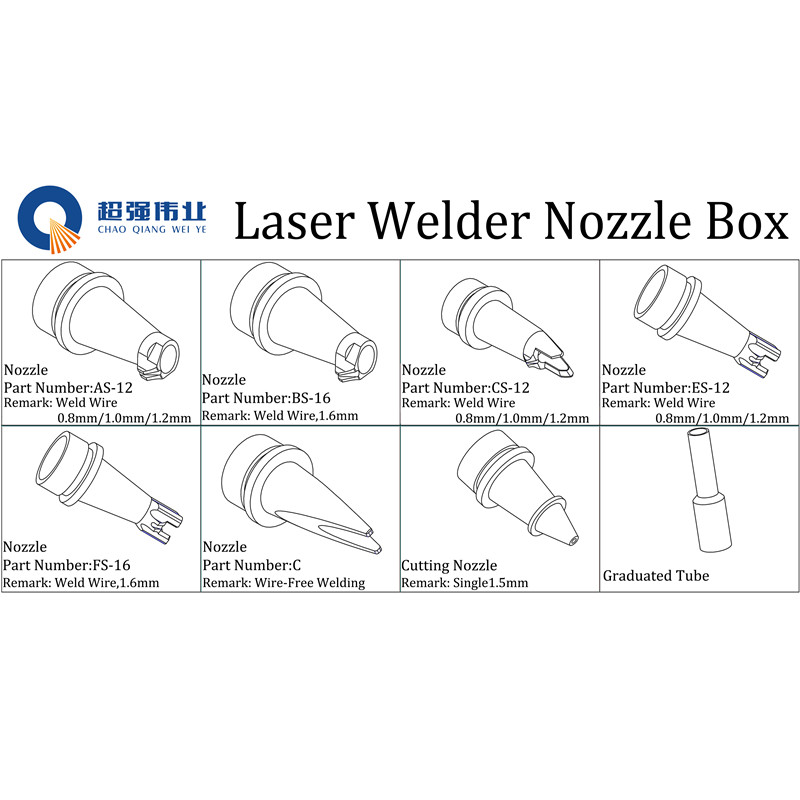

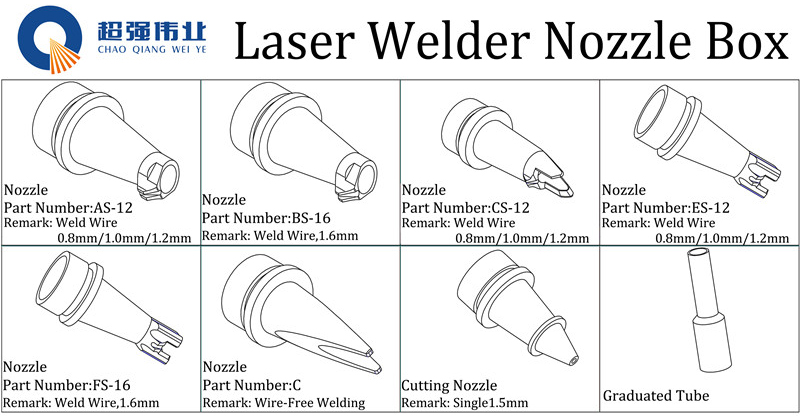

Inombolo yeCandelo:AS-12

Phawula: Weld Wire 0.8mm/ 1.0mm/1.2mm

Inombolo yecandelo:BS-16

Phawula: Ucingo lweWeld, 1.6mm

Inombolo yecandelo:BS-16

Phawula: Ucingo lweWeld, 1.6mm

Inombolo yeCandelo: ES- 12

Phawula iWeld Wire 0.8mm/1.0mm/1.2 nm

Inombolo yeCandelo:FS- 16

Phawula: Ucingo lweWeld, 1 6mm

Inombolo yeCandelo: C

Phawula: I-Wire-Free Welding

Inombolo yeCandelo: C

Phawula: I-Wire-Free Welding

Inombolo yeCandelo: C

Phawula: I-Wire-Free Welding

Isidanga Tube

Impembelelo ye-nozzle yomshini wokusika i-laser kwi-laser cutting?

Umatshini wokusika weLaser osetyenziswayo ngokuqinisekileyo uya kusebenzisa umbhobho, imarike yahlulahlulwe ikakhulu ibe yi-supersonic nozzle kunye ne-subsonic nozzle, i-supersonic njengoko igama lithetha ukuba isantya sokuhamba kwegesi sikhulu kunesantya sesandi, i-subsonic nozzle yinqanaba lokuhamba kwegesi lincinci. kunesantya sesandi.Imilomo emibini yohlulwe yaba ziindidi ezingaqhelekanga nezimbini.Makhe sijonge impembelelo ye-nozzle yomshini wokusika i-laser xa ukusika i-laser.

Umatshini wokusika we-laser kabini

Ngaphambi kokuthetha ukuba i-nozzle yomshini wokusika i-laser inempembelelo kwi-laser cutting, okokuqala uthi igesi encedisayo idlala indima yokusika.Okokuqala, ukukhawuleza izinga lokupholisa kwendawo yokusika, ukunciphisa indawo echaphazelekayo yokushisa, kwaye uncede wenze i-smooth cutting surface.Okwesibini, ioksijini njengegesi encedisayo inokunyusa ubushushu bokusabela, ilungele ukusika ipleyiti eshinyeneyo.Okwesithathu, igesi ye-inert njengegesi encedisayo inokuthintela i-oxidation yomsebenzi, igcine iimpawu zezinto eziphathekayo ngokwazo.

1. Impembelelo ye-oxide viscosity

Phakathi kwazo zonke iiparitha zetekhnoloji zokusika i-laser, uxinzelelo lwegesi oluncedisayo kunye neempawu zokuhamba kwegesi zizinto ezibalulekileyo ezichaphazela umgangatho wokusika.Xa usikwa iipleyiti zentsimbi ezishinyeneyo, ezifana nekhabhoni yentsimbi, ioksijini isetyenziswa njengegesi encedisayo kuba i-iron oxides ine-viscosity esezantsi kwaye kulula ukuyisusa kwi-cut.

Ngaphantsi kweemeko eziqhelekileyo, nangona icala le-carbon steel laser cutting incision iqulethe i-short layer ye-iron oxide, kwiimeko ezininzi, umgangatho we-laser cutting steel surface uyamkeleka.Kodwa ngenxa yokuba insimbi engenasici ine-chromium, kwaye i-chromium oxide etyhidiweyo ine-viscosity ephezulu, kulula ukuyidibanisa kudonga lwecala lokusikeka, ngoko ke ukusetyenziswa okufanayo kwe-oksijini njengegesi encedisayo, umgangatho wokucubungula intsimbi ubi kakhulu kunentsimbi ye-carbon.Ukuba uxinzelelo lwegesi aluphezulu, kunzima ukususa ezi oxides.

Ingxaki efanayo iya kwenzeka xa usika i-aluminium kunye ne-titanium alloy, kuba i-aluminium etyhidiweyo kunye ne-titanium oxide nayo ine-viscosity ephezulu, ukuze ufumane umgangatho wokusika kakuhle kufuneka ufune uxinzelelo oluphezulu lwegesi encedisayo.Ngapha koko, i-Cr, Al, Ti alloys kunzima ukusika izinto.

Umboniso weteknoloji yokusika umatshini weLaser

2. Impembelelo ye-slag viscosity kwimeko yokunyibilika

Ukusika i-laser ngegesi engasebenziyo njengegesi encedisayo kunokunciphisa impembelelo yeengxaki ezingentla ukuya kwinqanaba elithile, kodwa igesi engasebenziyo idla ngokufuna ukusebenza kuluhlu oluphezulu kakhulu lwe-8 ukuya kwi-25Bar, kunye nesinyithi esityhidiweyo ekusikeni sinokususwa. phantsi kwentshukumo ye-airflow shear force.Ngenxa yokuba akukho oksijini ekuhambeni, ii-oxide zetsimbi aziyi kubumba kwi-cut.Ngokubanzi, intsimbi ecocekileyo kwimeko etyhidiweyo ine-viscosity ephantsi kakhulu kune-oxide yayo kwaye inokuvuthelwa ngokulula ngakumbi, ngoko kulula ukwenza indawo encinci echaphazelekayo yokushisa kunye nomphezulu osikiweyo ngaphandle kokungcola kwe-oxide.

Ulwakhiwo olukhethekileyo lombhobho we-supersonic luphantse luguqule uxinzelelo lwegesi encedisayo lube ngamandla aguqukayo, luvuthulule i-slag, kwaye lufezekise indawo egqibeleleyo yokusika i-laser.